Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Sanitary napkin,Baby diaper,Adult diaper

Minimum order quanity: 1000.00 kgs

Packing details: Paper board with transparent film

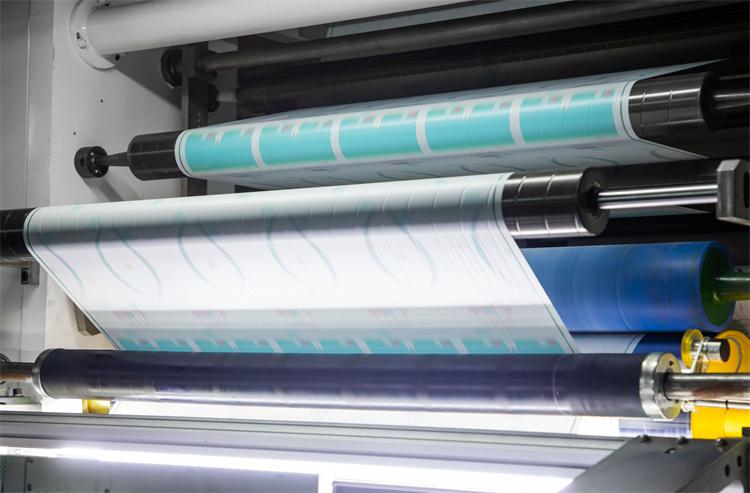

Thermal bond non woven fabric is generated by bicomponent fiber or PP with PET fiber. They have higher elongation in the CD and lower elongation in the MD.

Composition: ES-fiber

Weight:18gsm

Width: 65mm-2000mm

Inner core diameter: 76mm

Outer diameter: 580/780mm

Loading quantity:12tons/40HQ

|

Items |

Unit |

Requirement |

Result |

|

|

Color |

|

White |

white |

|

|

Core inside diameter |

mm |

76±1 |

76 |

|

|

Roll slit width |

mm |

200±2 |

200 |

|

|

Basic weight |

g/m2 |

18±1.5 |

18 |

|

|

Tensile strength |

MD |

N/5*10cm |

≥25 |

30.6 |

|

CD |

≥3 |

4.8 |

||

|

Elongation |

MD |

% |

≥22 |

29.225 |

|

CD |

% |

≥75 |

82.725 |

|

|

Hydrophilicity |

|

Hydrophilic |

||

CATEGORY Soft hydrophilic non woven fabric APPLICATION Topsheet wrapping non woven fabric for medium grade diapers, pull-ups, sanitary napkin and under pads. WIDTH BASI...

1. Spunlace non woven fabric is made by viscose and polyester. 2.Spunlace non woven fabric can be cross type or parallel type. 3.Spunlace non woven fabric can be plain or dot. 4.Ap...

Weight: 18g/M2 to 60g/M2 as request Composition: 100% 6 Denier PE/PP Bicomponent fiber Color: white, blue,green Width: 25mm-2000mm or customized Application:baby diaper, adult d...

WEIHONGLAI export diaper non woven for customerin Bolivia. Polypropylene is the key component of thesterile quality of spunbond non woven fabrics. The material we offer has s...

Hydrophobic SMMS non Woven fabric is the abbreviation of “Spunbond + Meltblown +Meltblown+ Spunbond Non woven”, that is a combined nonwoven fabric which two layers spunbond have ...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China