Introduction. Enhanced Absorbency and Leakage Prevention. Softness and Comfort. Sustainability and Environmental Friendliness. Conclusion....

Introduction. Enhanced Absorbency and Protection. Eco-Friendliness and Sustainability. Improved Manufacturing Efficiency. Conclusion....

Introduction. Absorbency and Breathability. Softness and Comfort. Manufacturing Efficiency and Cost-effectiveness. Conclusion....

Introduction. Enhanced Absorbency and Leakage Protection. Improved Comfort and Breathability. Design Versatility and Customization. Conclusion....

Introduction. Superior Absorbency. Enhanced Breathability. Unmatched Durability. Conclusion....

Introduction. Enhanced Absorbency and Leakage Protection. Breathability and Skin-Friendliness. Sustainability and Environmental Impact. Conclusion....

Unveiling the Benefits of Backsheet Nonwoven Fabric in Diaper Production Introduction: The Significant Role of Backsheet Nonwoven Fabric When it comes t...

Introduction. Enhanced Comfort and Softness. Superior Absorbency and Leakage Protection. Cost-effectiveness and Sustainability. Conclusion....

Introduction. Enhanced Absorbency and Comfort. Improved Fit and Flexibility. Sustainability and Environmental Benefits. Conclusion....

Introduction. Properties of Non Woven Raw Material. Benefits of Non Woven Raw Material in Diapers. Impact on Diaper Quality. Conclusion....

Introduction. Enhanced Comfort and Softness. Excellent Absorbency and Leakage Protection. Durability and Cost-effectiveness. Conclusion....

Introduction. Enhanced Waterproofing. Improved Softness and Comfort. Enhanced Durability and Strength....

Introduction. What is SSS Non Woven Fabric?. Advantages of SSS Non Woven Fabric in Diaper Manufacturing. Conclusion....

Introduction. Composition of ES Fiber Non Woven Fabric. Manufacturing Process. Advantages in Diaper Production. Conclusion....

Introduction. Superior Absorbency and Moisture Retention. Softness and Breathability for Enhanced Comfort. Durability and Cost-Effectiveness. Conclusion....

1. Comfort and Convenience. 2. Absorbency and Leakage Protection. 3. Hygiene and Safety....

Untreated fluff pulp,untreated fluff pulpprice,fluff pulp Untreated fluff pulp features: Untreated fluff pulp is used for babydiaper, sanitary napkin and adult diaper. Loading quanti...

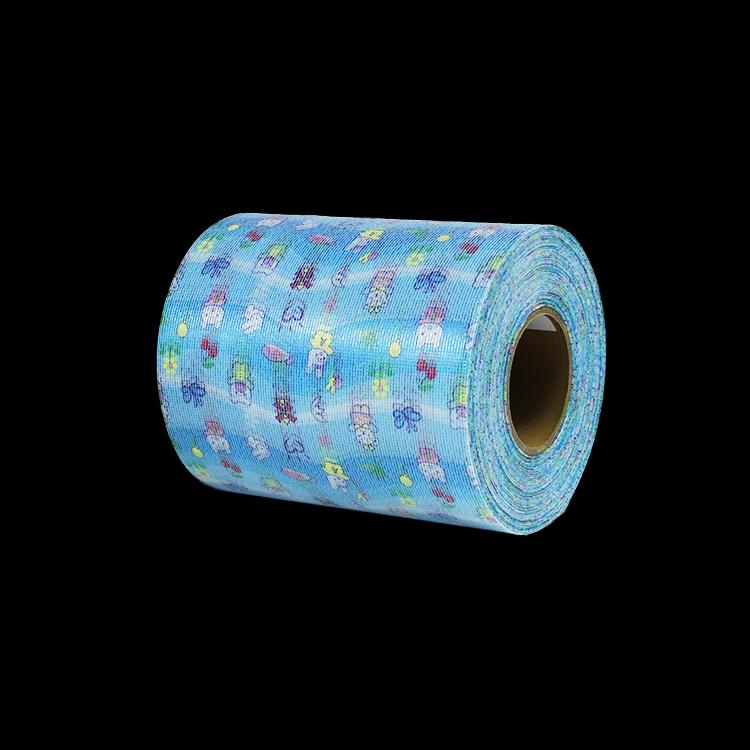

Colorful breathable PE film features: 1.Excellent breathability High elongationExtra soft Safe for sensitive skin 2.Free from chemical agents 3.Micro porous , these composite s...

Knitted frontal tape also called LOOP and magic frontal tape, has samefunction as pp frontal tape, to attached to the front of the diapers withadhesive, but this is a new generation of ...

1. Hydrophilic spunbond non woven fabric topsheet is the opposite of water repellent non woven fabric. The hydrophilic spunbond non woven fabric topsheet is to add a hydrophilic agent i...

Introduction. Composition of ES Fiber Non Woven Fabric. Manufacturing Process. Advantages in Diaper Production. Conclusion....

Hot airnon woven fabric ismade of compound fibers which causes no stimulation or allergy to human body. They have achieved the national standard of hygiene pads production. They tend to...

WEIHONGLAI white color spunbond hydrophilic non woven fabric has been packed well. It is ready to be shipped to Jordan customer. The white color spunbond hydrophilic non woven fabric p...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China