Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-19

Unleashing the Potential of Non Woven Fabric in Diaper Manufacturing

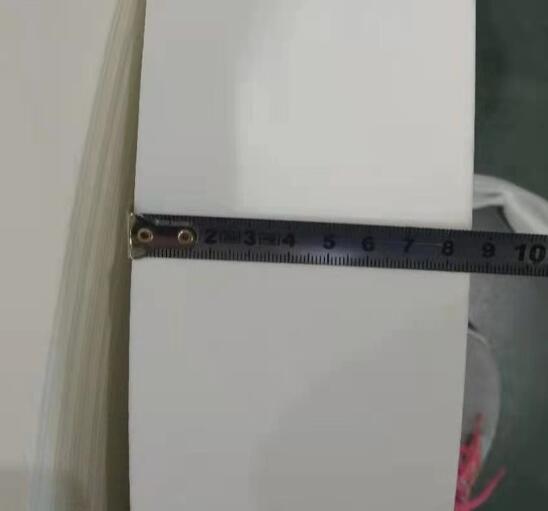

Non woven fabric has emerged as a game-changer in the diaper manufacturing industry. Its unique properties and versatility have revolutionized the way diapers are produced, making them more comfortable, absorbent, and cost-effective. This article aims to explore the various applications and benefits of non woven fabric in diaper manufacturing.

One of the key advantages of using non woven fabric in diapers is the enhanced comfort and softness it provides to babies. The fabric is extremely gentle on the delicate skin, reducing the risk of irritation or rashes. Its smooth texture offers a cushion-like feel, ensuring a snug fit and minimizing leakage. Moreover, non woven fabric is breathable, allowing air circulation and preventing the build-up of moisture, keeping the baby's skin dry and comfortable.

Non woven fabric excels in its ability to provide superior absorbency and leakage protection in diapers. The fabric is engineered with high-performance absorbent polymers that quickly capture and lock away liquid, keeping the baby's skin dry for extended periods. The unique structure of non woven fabric ensures even distribution of the absorbed moisture, reducing the risk of leaking and providing peace of mind to parents. This capability makes non woven fabric an ideal choice for overnight diapers and for babies with heavy wetting tendencies.

In addition to its performance advantages, non woven fabric presents significant cost-effectiveness and sustainability benefits for diaper manufacturers. Compared to traditional woven fabrics, non woven fabric is more economical to produce, as it involves a simplified manufacturing process and utilizes fewer resources. It is also lightweight, reducing transportation costs. Furthermore, non woven fabric can be easily recycled, making it an environmentally friendly option that aligns with the growing demand for sustainable products.

The utilization of non woven fabric in diaper manufacturing has opened up new possibilities for comfort, absorbency, cost-effectiveness, and sustainability. Its ability to enhance comfort, provide superior absorbency, and reduce leakage has made diapers more reliable and convenient for parents. Additionally, the cost-effectiveness and sustainability benefits make non woven fabric an attractive choice for manufacturers. As the demand for high-quality diapers continues to grow, non woven fabric is set to play a pivotal role in shaping the future of the diaper industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China