Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-01

Introduction:

The manufacturing of non-woven diapers requires specific key ingredients that contribute to the quality and functionality of the final product. These ingredients play a vital role in ensuring comfort, absorbency, and leakage prevention. In this article, we will explore the key ingredients involved in the manufacturing process of non-woven diapers and their significance.

Superabsorbent polymers (SAPs) are one of the crucial ingredients in non-woven diaper manufacturing. These polymers have the ability to absorb and retain large quantities of liquid. SAPs are integrated into the diaper's core to enhance its absorbency. They can absorb many times their own weight in fluids, converting them into a gel-like substance. This gel prevents any leakage and keeps the baby's skin dry and comfortable. SAPs also help in distributing the liquid evenly throughout the diaper, reducing the risk of sagging or clumping.

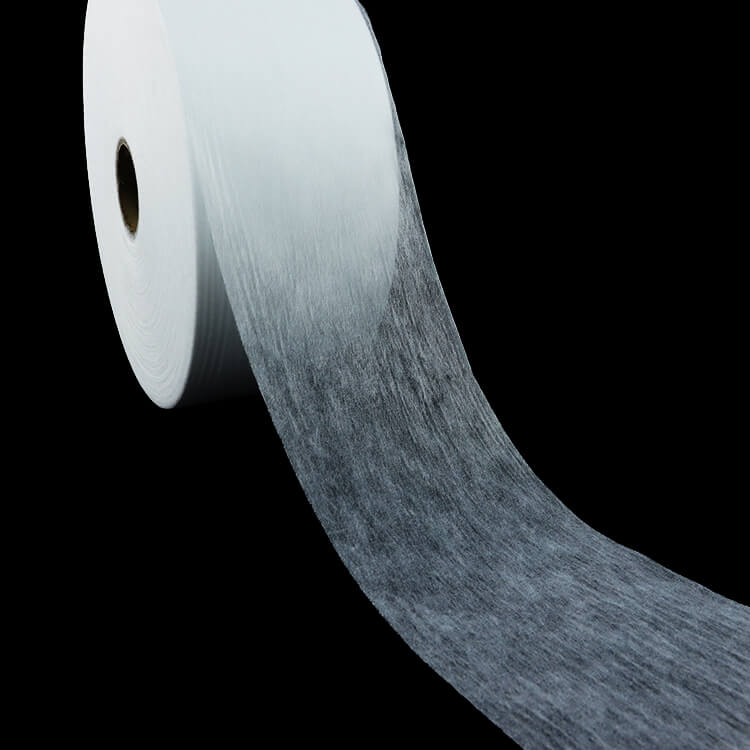

Non-woven fabrics are another essential ingredient used in the production of diapers. These fabrics are made by bonding together fibers using heat, chemicals, or mechanical processes, without weaving or knitting. Non-woven fabrics provide several advantages over traditional woven fabrics, such as better breathability, softness, and cost-effectiveness. These fabrics allow air circulation, reducing the risk of rashes and maintaining a comfortable environment for the baby. They also provide a soft and gentle touch to the baby's delicate skin, preventing any irritation or discomfort.

Elastic materials are incorporated into non-woven diapers to provide a secure and snug fit. These materials are usually placed in the waistband and leg cuffs of the diaper. Elastic bands made from natural or synthetic rubber are used to ensure flexibility and stretchability. They help in preventing leakage by creating a barrier that fits closely to the baby's body. Elastic materials allow freedom of movement without compromising on the diaper's integrity. They are designed to be gentle on the baby's skin and prevent any chafing or irritation.

Conclusion:

In conclusion, the key ingredients involved in non-woven diaper manufacturing, such as superabsorbent polymers, non-woven fabrics, and elastic materials, are vital for ensuring the functionality and comfort of the final product. These ingredients work together to provide excellent absorbency, prevent leakage, maintain dryness, and promote the overall well-being of the baby. Manufacturers continue to innovate and improve these ingredients to meet the ever-changing demands of parents and provide the best possible experience for both babies and caregivers.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China