Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-07

Unleashing the Potential of Small Ear Spunbond Non Woven in Diaper Materials

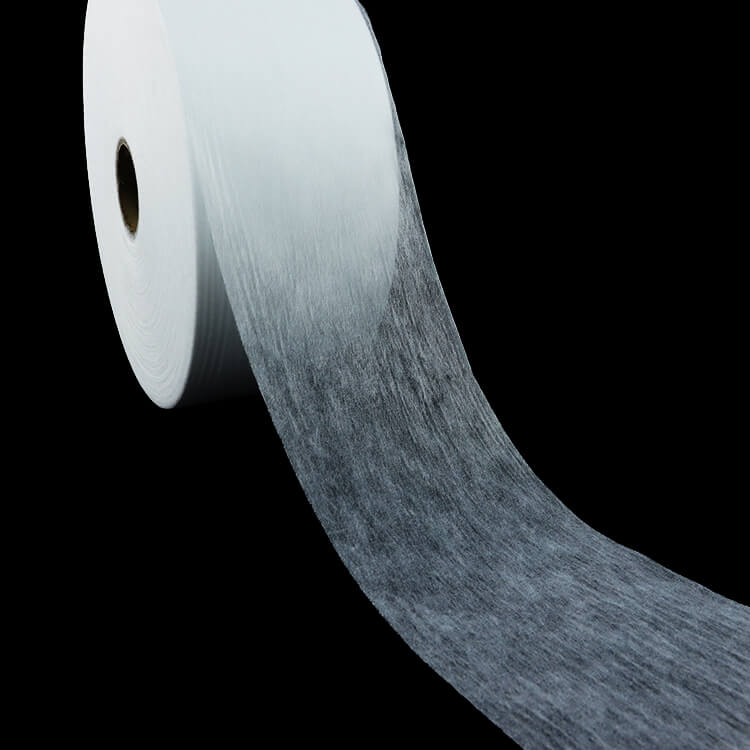

The use of nonwoven materials in diaper manufacturing has revolutionized the industry, providing enhanced comfort and absorption. Among these materials, spunbond nonwoven fabrics have gained significant attention due to their excellent strength and softness. However, traditional large-sized spunbond nonwovens pose challenges in terms of cost and efficiency. In this article, we explore the potential of small ear spunbond nonwovens in diaper materials, highlighting their benefits and applications.

Small ear spunbond nonwovens offer several advantages over their larger counterparts. Firstly, their reduced size allows for better utilization of the raw material, resulting in higher production efficiency. Manufacturers can achieve a higher yield from each roll of material, reducing waste and optimizing costs. Additionally, the smaller size enables improved handling during production processes, leading to increased operational efficiency. These factors make small ear spunbond nonwovens a cost-effective choice for diaper manufacturers.

The softness of diapers is a crucial factor in ensuring the comfort of babies. Small ear spunbond nonwovens excel in this aspect by offering enhanced softness compared to larger counterparts. The reduced size of the fibers provides a smoother and gentler surface, reducing friction and irritation on the baby's skin. This feature contributes to a more comfortable wearing experience and minimizes the risk of diaper rash. Manufacturers can leverage the superior softness of small ear spunbond nonwovens to enhance the overall quality of their diaper products.

Small ear spunbond nonwovens provide diaper manufacturers with a high level of versatility and customization options. The smaller size allows for better control over the fabric's thickness and density, enabling manufacturers to tailor the material according to specific requirements. This versatility opens up avenues for innovation, such as designing diapers with targeted absorbency zones or enhancing breathability in certain areas. Furthermore, small ear spunbond nonwovens can be easily combined with other materials, such as superabsorbent polymers or elastic components, to create diapers with enhanced performance and fit.

The use of small ear spunbond nonwovens in diaper materials offers numerous advantages for manufacturers. Enhanced efficiency and cost-effectiveness, improved softness and comfort, as well as versatility and customization, are key benefits that contribute to the overall quality of diaper products. As the industry continues to evolve, harnessing the potential of small ear spunbond nonwovens will empower manufacturers to meet the evolving needs and expectations of parents and caregivers, ensuring the well-being and happiness of babies around the world.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China