Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-21

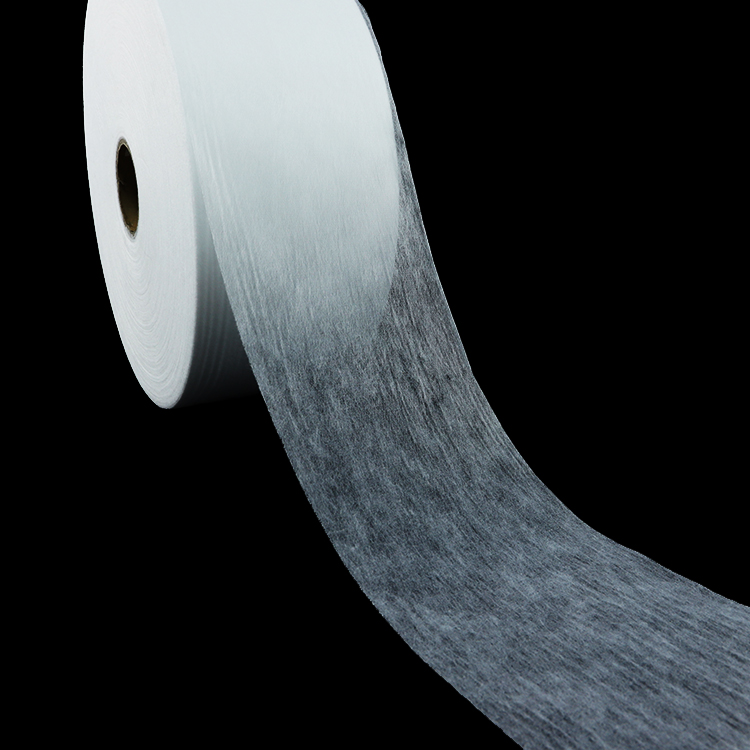

Maximizing Efficiency with Thermal Bond Nonwoven in Diaper Production

In recent years, the demand for disposable diapers has been steadily increasing. To meet this growing demand, diaper manufacturers are constantly seeking ways to improve production efficiency without compromising product quality. One such solution that has gained popularity in the industry is the use of thermal bond nonwoven material in diaper production. This article explores how thermal bond nonwoven can maximize efficiency in the manufacturing process, resulting in cost savings and improved productivity.

One key advantage of using thermal bond nonwoven in diaper production is its enhanced absorbency compared to traditional materials. The thermal bonding process creates a durable fabric that allows for improved fluid retention, reducing the frequency of diaper changes. Additionally, the use of thermal bond nonwoven enables manufacturers to incorporate perforations into the material. These perforations enhance breathability and promote better airflow, keeping the baby's skin dry and comfortable.

The thermal bond nonwoven material offers significant advantages in terms of the production process. Firstly, it can be directly bonded to other layers of the diaper, eliminating the need for additional adhesive materials. This not only streamlines the production process but also reduces the consumption of adhesive, resulting in cost savings. Secondly, thermal bond nonwoven is compatible with high-speed diaper manufacturing machines, allowing for increased production rates. The material's strength and durability ensure smooth processing and minimize downtime due to material breakage or tearing.

By incorporating thermal bond nonwoven into diaper production, manufacturers can achieve significant cost savings. The elimination of adhesive materials reduces procurement costs, and the enhanced production efficiency translates to lower labor and energy costs. Furthermore, thermal bond nonwoven is eco-friendly compared to traditional materials. It is biodegradable and does not contribute to environmental pollution. This aligns with the increasing consumer demand for sustainable and environmentally responsible products.

In conclusion, the use of thermal bond nonwoven in diaper production offers numerous benefits, including enhanced absorbency, improved perforation, efficient production process, cost savings, and eco-friendliness. As the demand for disposable diapers continues to rise, maximizing efficiency in the manufacturing process becomes increasingly important. Thermal bond nonwoven material provides a viable solution to meet these demands, enabling diaper manufacturers to produce high-quality products while achieving cost savings and improving productivity.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China