Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-22

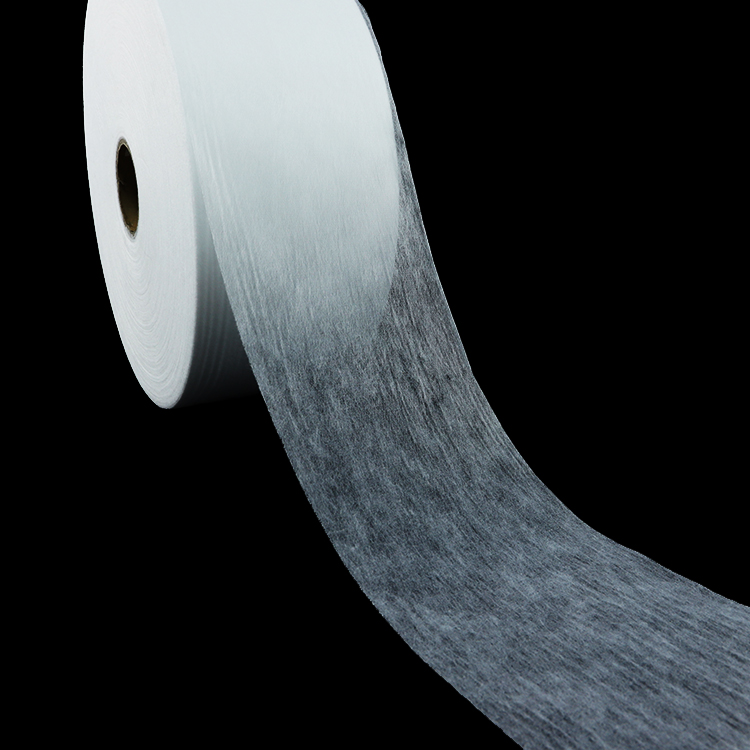

Thermal bond nonwoven is a versatile material widely used in various industries due to its excellent properties. In the diaper manufacturing industry, thermal bond nonwoven plays a crucial role, offering multiple applications that enhance the quality and performance of diapers. This article will provide an overview and exploration of the versatile applications of thermal bond nonwoven in diaper manufacturing.

One of the primary applications of thermal bond nonwoven in diaper manufacturing is to enhance the absorbency of the diaper. Thermal bond nonwoven is composed of synthetic fibers that can be engineered to have high porosity, allowing for increased absorption capacity. The material efficiently traps moisture, preventing leakage and ensuring a dry and comfortable experience for the baby. Furthermore, the thermal bonding process enhances the stability and integrity of the nonwoven material, minimizing the risk of sagging or bulking when wet.

Another significant advantage of using thermal bond nonwoven in diapers is its softness and comfort. The material has a gentle touch against the baby's skin, preventing irritation or discomfort. Thermal bond nonwoven can be engineered to have a smooth surface, providing a soft and silky feel for the baby. Additionally, the thermal bonding process allows the fibers to be distributed evenly, resulting in a uniform texture throughout the material. This uniformity enhances the overall comfort of the diaper, ensuring that the baby's delicate skin is well-protected.

Thermal bond nonwoven is also utilized in diaper manufacturing to improve elasticity and fit. The material can be designed with elastic properties, allowing it to stretch and conform to the baby's body shape. This elasticity ensures a snug fit, reducing the chances of leakage and providing better protection. Moreover, thermal bond nonwoven can be incorporated into the diaper design to reinforce specific areas that require extra support, such as the leg cuffs or waistband. By enhancing the elasticity and fit, thermal bond nonwoven contributes to the overall efficiency and performance of diapers.

In conclusion, thermal bond nonwoven plays a vital role in the manufacturing of diapers. Its versatile applications enhance the absorbency, softness, comfort, elasticity, and fit of diapers, ultimately improving the overall performance and quality. The combination of high absorbency, gentle touch, and secure fit provided by thermal bond nonwoven ensures that babies stay dry, comfortable, and protected. As diaper technology continues to advance, thermal bond nonwoven will undoubtedly remain an indispensable component in the industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China