Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-02

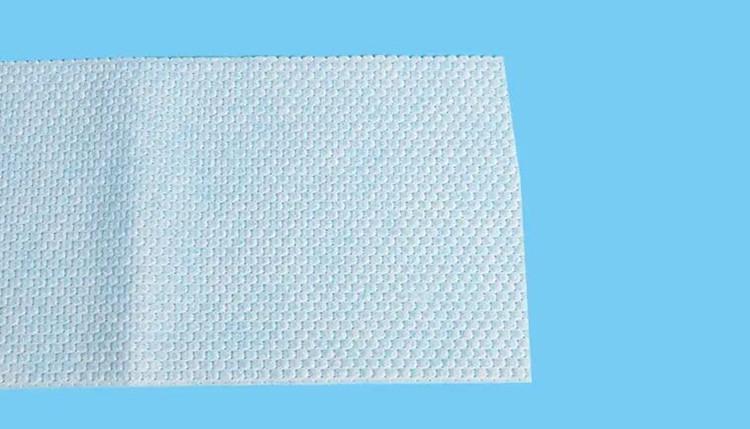

In the domestic disinfection supply center, the most commonly used packaging materials besides cotton are non woven fabric. When hospitals choose non woven fabric, they often pay attention to thickness, that is, gram weight. So is it thicker the better? the answer is negative. Here's why it's not the thicker the better when it comes to choosing.

The increase in the thickness of the non-woven fabric means that the weight per unit area increases, and the corresponding strength also increases, but due to its own structural characteristics, the increase in thickness does not mean an increase in the barrier properties of microorganisms. For example, when a thickened non woven fabric is used, the increase in the weight of its spunbond layer cannot effectively increase its antibacterial performance. Only when the pore size of the key filter layer (ie, the meltblown layer) can effectively filter the intrusion of microorganisms and dust, its resistance to Bacterial properties meet the requirements. As the thickness increases, the air permeability of the packaging material will also be affected, and the probability of wet packs will also increase.

In clinical use, the non woven fabric will be damaged after sterilization. For this kind of damage, it is mainly because the microscopic fine plastic fibers will shrink to a certain extent after high temperature sterilization, which is manifested in the use of sterilized non woven fabric. It is more brittle than before sterilization, so applying too much force or unreasonable handling method during use will cause destructive damage to the packaging material. In addition, the use of burrs on the edge and sharp instruments will also cause its damage. damaged. In this case, it is more recommended that the clinical package should be tight and light, and use the double layer packaging recommended by the standard, which will greatly reduce the probability of damage. If the problem of breakage is only solved by increasing its thickness, in addition to ensuring the antibacterial performance, it is also necessary to closely observe the probability of wet packs.

All in all, non woven fabric are not the thicker the better. On the premise of ensuring the antibacterial performance and tensile strength, the material with good air permeability can reduce the wet wrapping phenomenon of the non woven fabric.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China