Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-02

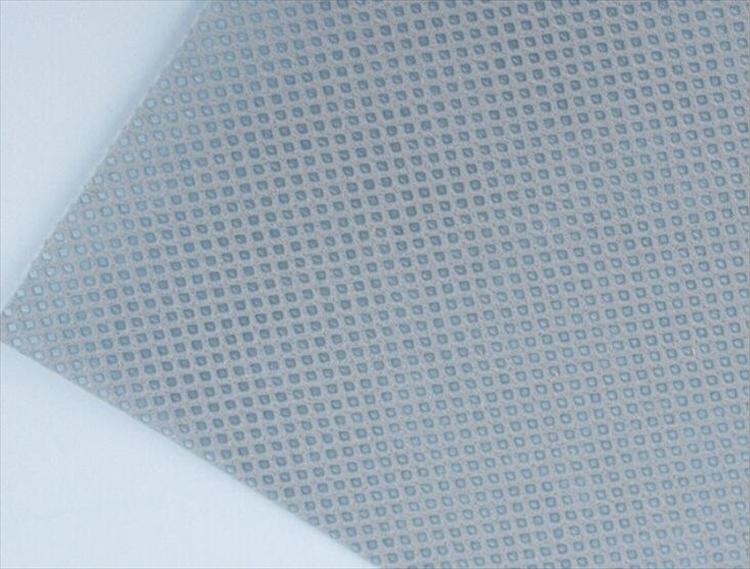

In recent years, with the rapid development of infrastructure in my country, there is also a huge demand for backsheet non woven fabric. At this stage, it still occupies most of the market share in my country and has broad prospects, but there are still some technical lag and product quality defects in specific production. This article describes how to optimize electrical control in a backsheet non woven fabric production line.

In order to ensure the strength index of backsheet non woven fabric, the drying temperature, crystallization temperature, melting temperature and other temperatures of sliced PET need to be precisely controlled. The PLC integrated temperature module is selected to collect real-time temperature, and the PLC output module outputs high-frequency pulses to control the solid-state relay to achieve the purpose of precise temperature control. This can greatly extend the service life of electrical components, avoid serious temperature lag, temperature stability, The accuracy is also significantly improved, and the temperature deviation is controlled within ±0.1°C.

The real-time air pressure signal is collected and sent to the PLC, and the PID automatic adjustment is programmed through the PLC. The analog signal is output to control the pneumatic membrane valve. The control pressure is above 5 bar, and the air pressure control is accurately and effectively completed. quality has been greatly improved.

At present, the key difficulty in the production of backsheet non woven fabric is to feed the reinforcing material smoothly, which requires controlling the speed between the rollers, so as to achieve the purpose of controlling the tension and reducing the breakage rate. The feeding part is selected to use multiple sets of servos to control the yarn guide rollers respectively. The control hardware mainly includes: programmable logic controller (PLC), servo driver, and servo motor. There is no need for sensors, which effectively avoids serious lag problems in the system. In addition, special software is used to set a series of parameters such as acceleration and deceleration time and torque curve of the servo motor, and a lot of optimization work has been carried out on the parameters related to the parameter servo drive. Through the real-time adjustment of the torque of the servo motor, the speed between the rollers is precisely controlled, the yarn is uniform and stable, and the average fiber tension is 60-66cN, which finally solves the key problem of yarn breakage.

From the aspects of economy and control accuracy, a stepper motor is selected to achieve precise position control. To improve the market competitiveness of the backsheet non woven fabric production line, we cannot blindly pursue high precision and high stability of control, but also need to consider economic factors and practicality.

Better control system communication can quickly and accurately transmit data, successfully avoid external factors affecting the stability of the system, and the control equipment runs stably to produce high-quality underlying non-woven fabrics. Taking Siemens PLC programmable controller as an example, it uses Ethernet communication with high anti-interference to complete signal transmission, which not only makes the transmission data and signals not easy to be interfered, but also reduces wiring, greatly simplifies programming, and reduces the transmission rate from Kbps increased to Mbps. Moreover, the system is controlled by the touch screen, and the real-time torque parameters and real-time speed parameters of the three leading yarn rollers can be set and fed back through configuration. The main touch screen also contains protection functions such as chain protection and safety emergency stop, which is very convenient. The technicians can adjust the process parameters. At the same time, the DCS is used for decentralized control, and the signals are uniformly connected to the industrial-grade routing. The remote monitoring and adjustment of the on-site status are realized through the Internet, which greatly reduces the maintenance cost in the later period.

Of course, when optimizing the electrical control of the backsheet non woven fabric production line, the accuracy of the mechanical design and the rationality of the process parameters should also be considered, so that all majors can cooperate with each other to create a non-woven production line that strives for excellence, so that the backsheet non woven fabric can be better development of.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China