Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-03

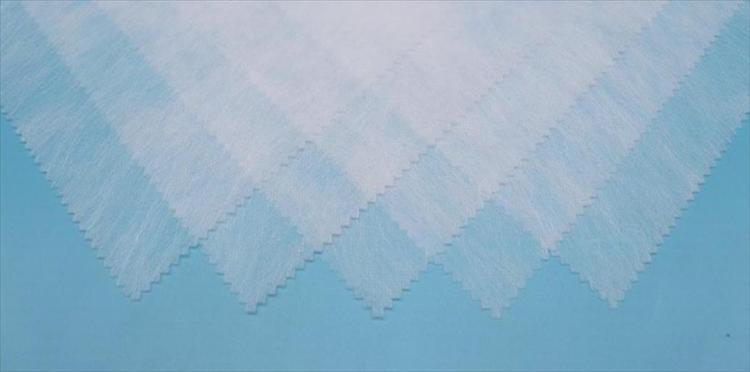

With the continuous promotion and deepening of the development concept of "environmental protection and energy saving", polypropylene laminated non woven has been widely used in many fields such as clothing, household products, medical and health and agriculture due to its low production cost, good mechanical properties and non-toxicity. widely used. This paper briefly describes the preparation technology of biodegradable polypropylene laminated non woven.

The processing technology of spunbond non-woven fabric with polypropylene as raw material is to first heat the polymer (polypropylene and return material) to melt it at high temperature, extrude it under the action of a metering pump, and then cool it by blowing from the side. And enter the high-speed flow field to draw the wire into a net, and finally make it through reinforcement treatment.

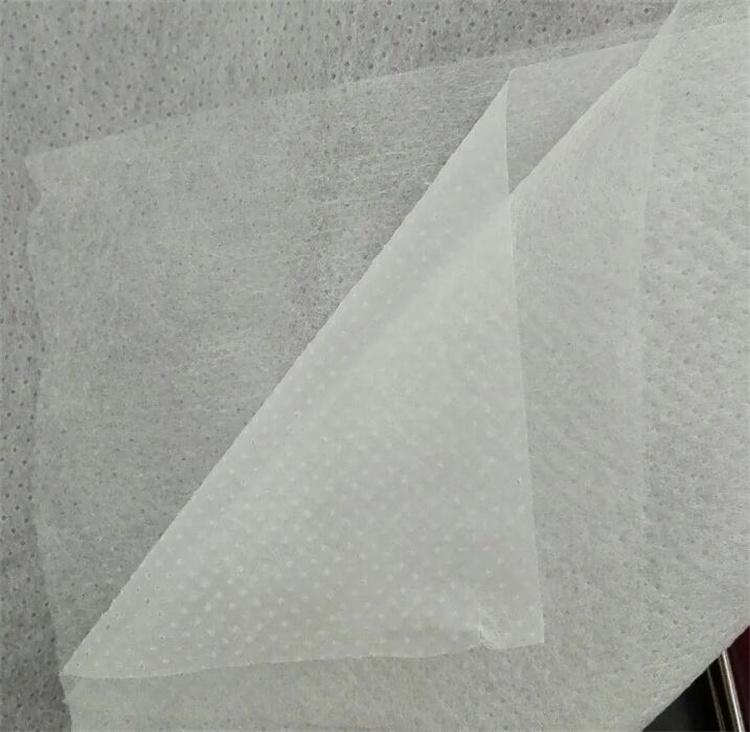

Because the molecular structure of polypropylene is saturated carbon-carbon single bond, the relative molecular structure is relatively stable and difficult to degrade, so simple polypropylene spunbond cloth brings convenience to people's production and life, but also causes great environmental problems. Therefore, the preparation and research of environmentally friendly degradable polypropylene laminated non woven is particularly important. Polylactic acid is a biodegradable polymer, and polylactic acid has excellent biocompatibility and mechanical properties. It can be combined with polypropylene raw materials to prepare biodegradable polypropylene composite spunbond fabrics, thereby reducing the amount of Environmental pollution caused by propylene spunbond fabrics.

The biodegradable polypropylene composite spunbond fabric is prepared by using polylactic acid and polypropylene as raw materials and the condition of maleic anhydride graft as auxiliary agent by melt blending method of spinning machine. This article takes the preparation of biodegradable polylactic acid/auxiliaries/polypropylene laminated non woven as an example to illustrate the specific preparation process of biodegradable polypropylene laminated non woven:

(1) Slice the polylactic acid, polypropylene and the auxiliary maleic anhydride graft and mix them in an appropriate proportion;

(2) After pelletizing with an extruder, spinning with a spinning machine;

(3) Filtration through the melt filter, forming a net under the action of metering pump, reverse air and high-speed flow field draft;

(4) Perform hot-rolled bonding reinforcement, winding, reverse cloth slitting, etc. to obtain qualified spunbond non-woven fabrics.

The emergence of biodegradable polypropylene laminated non woven reduces the pollution caused by polypropylene laminated non woven to the environment and realizes the sustainable and healthy development of the environmentally friendly spunbond fabric industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China