Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-16

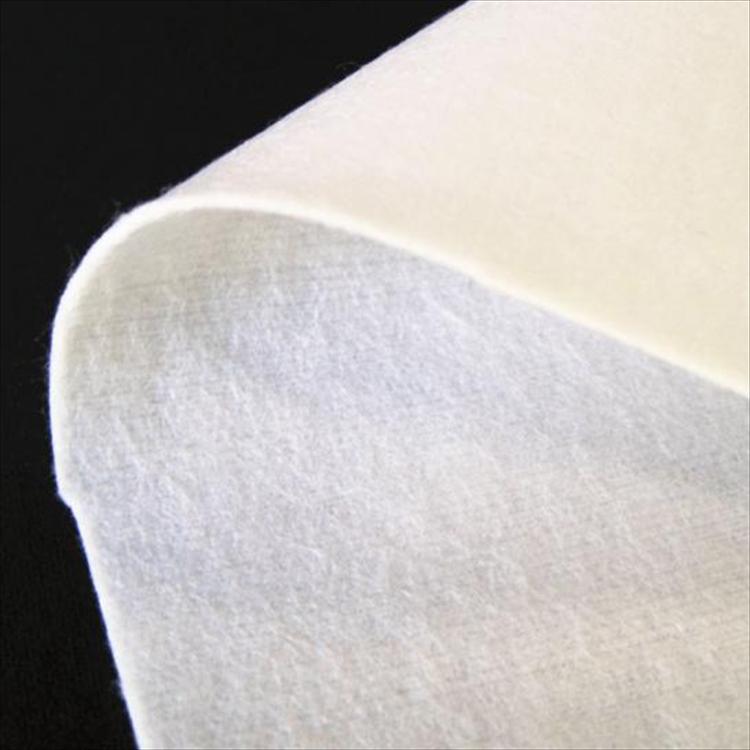

The hydrophilic spunlace non woven fabric was developed to expand the application field of spunlace, improve the comprehensive performance of spunlace, and endow it with new functions. Due to the different raw materials, the product can integrate the excellent properties of various materials. This paper briefly introduces the double-layer structure of the hydrophilic spunlace non woven fabric by taking the carded web and the hydrophilic spunlace non woven fabric of wood pulp fiber web/wood pulp paper as an example.

Because wood pulp fiber has good hygroscopicity and soft handfeel, its composite products have better hygroscopicity and handfeel than spunlace non-woven fabrics. The products are mainly used as wiping materials, diapers and sanitary napkin core materials. As early as 1996, DuPont began producing wood pulp/polyester spunlace wet wipes for the baby wipes market and the adult incontinence wipes market.

Up to now, the industry has widely adopted the method of pre-wetting and consolidating the carded fiber web by spunlace, then overlapping with the wood pulp fiber web, and finally drying after spunlace compounding. It is usually produced by wet-laid or air-laid. The study found that by introducing air-laid wood pulp fibers into pre-wetted and spunlaced carded webs for spunlace lamination, the process produced a composite nonwoven that looked like fluff was planted on the web. Again, the resulting product is very soft and strong, and the wood pulp fiber is inexpensive. Such products have developed vigorously in the field of hygiene products in recent years, and are widely used in wet wipes, wipes for infants and young children, etc.

The product is to add a layer of wood pulp paper on the carded fiber net, and then spunlace to make it hydrophilic. Studies have shown that the hydrogen bonds between adjacent cellulose molecules inside the wood pulp fibers are broken by water molecules during the hydroentangling process, which instead increases the flexibility of the wood pulp fibers; after drying, the cellulose molecules of the wood pulp fibers are Under the action of hydrogen bonds, the cross-linked structure is recombined to make the fibers stiff and straight, tightened and bonded to each other, effectively preventing fluffing and falling off; and the more the amount of fiber web, the higher the vertical and horizontal strength of the product.

In addition, wood pulp fiber has good hygroscopicity, low static electricity, and good air and moisture permeability of the product. Therefore, wood pulp paper hydrophilic spunlace non woven fabric is mainly used in the protection of food processing, medical and health industries, mainly including work clothes, protective clothing, surgical gowns and surgical curtains.

At present, hydrophilic spunlace non woven fabric has been widely used in medical supplies and hygiene industries. Knowing about the double-layer structure hydrophilic spunlace non woven fabric will help people make better use of this kind of material.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China