Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-07

In recent years, the sanitary products industry has developed rapidly, and the application of composite films in this industry has been basically popularized. PE Laminated sheet is mainly used in the field of diaper bottom film and medical materials, and the market prospect is very promising. Due to factors such as simple process and stable quality, many diaper factories are reducing the online lamination process and prefer to purchase PE Laminated sheet directly. From the perspective of customer demand, due to the implementation of the "separate two-child" policy and the intensification of population aging, the diaper market will still show double-digit growth in the future, and the application of hygienic composite films will also grow rapidly. This paper briefly introduces PE Laminated sheet from three aspects, in order to provide reference for related research.

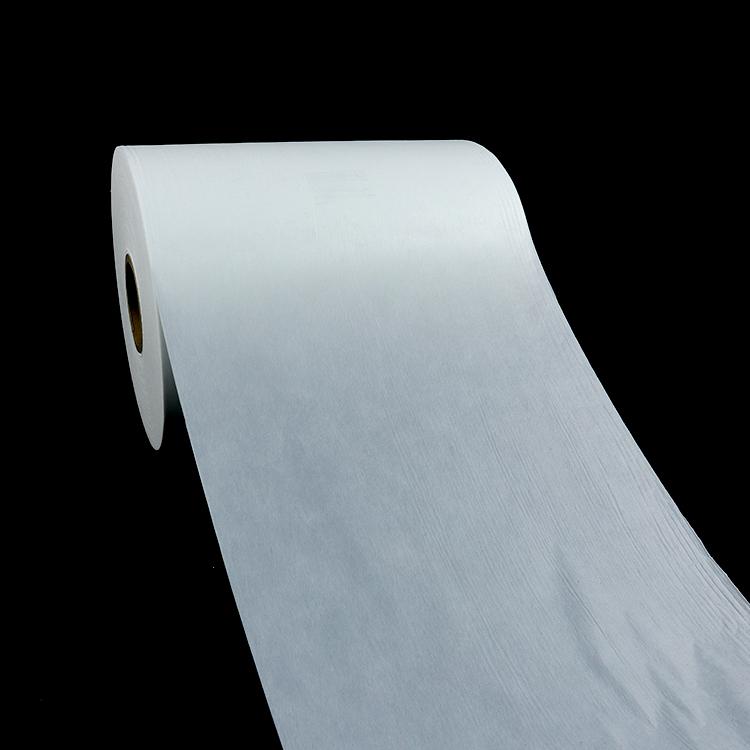

PE Laminated sheet product is a structure that combines PE film and non-woven fabric with hot melt adhesive under the action of pressure.

PE Laminated sheet is mainly divided into breathable film and non-breathable film, the main performance indicators are quantitative, ash and tensile strength. The most widely used nonwoven fabrics are spunbond nonwoven fabrics and a small amount of hot air nonwoven fabrics. The main performance indicators are quantitative and tensile strength. Of course, there are still some requirements such as hydrophobicity and softness, and the hot melt adhesive plays a bonding role in the composite film, and the glue amount is about 0.7~1.0g/square meter.

Compounding is divided into rolling compounding (hot melt adhesive is applied to the substrate through a roller) and spray compounding (hot melt adhesive is applied to the substrate through a nozzle). The advantages of rolling compounding are mainly: the amount of glue applied is accurate, The coating is uniform and the fluctuation is small; the advantage of spray compounding is that it feels softer. At present, more than 95% of the factories use rolling rubber compounding.The non-woven fabric is glued by the roller, and the temperature of the glue is reduced by cooling the steel plate, so as to prevent the phenomenon of glue back seepage and substrate wrinkling in the non-woven fabric caused by excessive temperature. The non-woven fabric is combined with the PE film on the composite roll, and then rolled.

At present, diaper manufacturers mainly have the following technical requirements for composite films: high bonding strength, aging resistance, high softness, no rewet, low odor, and no fluorescence.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China