Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-10

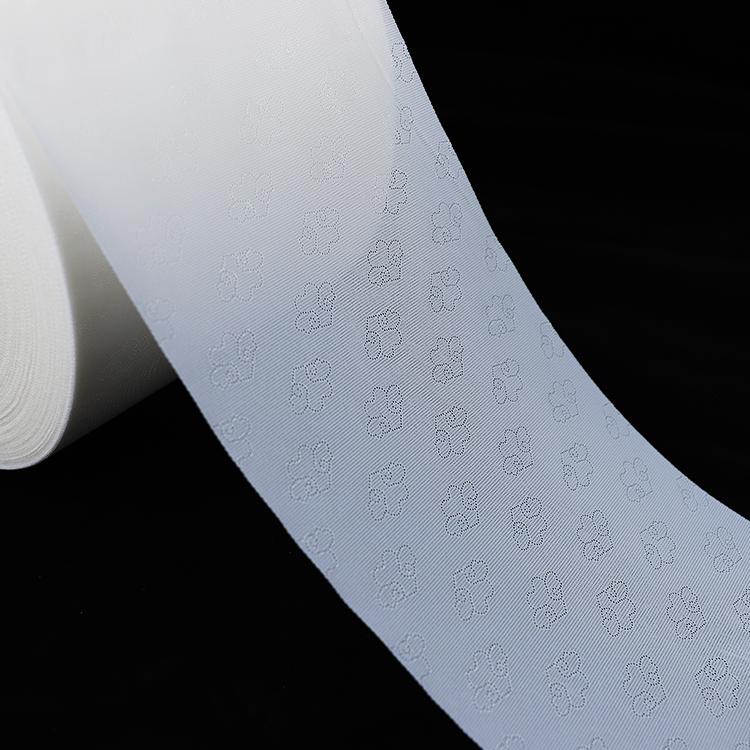

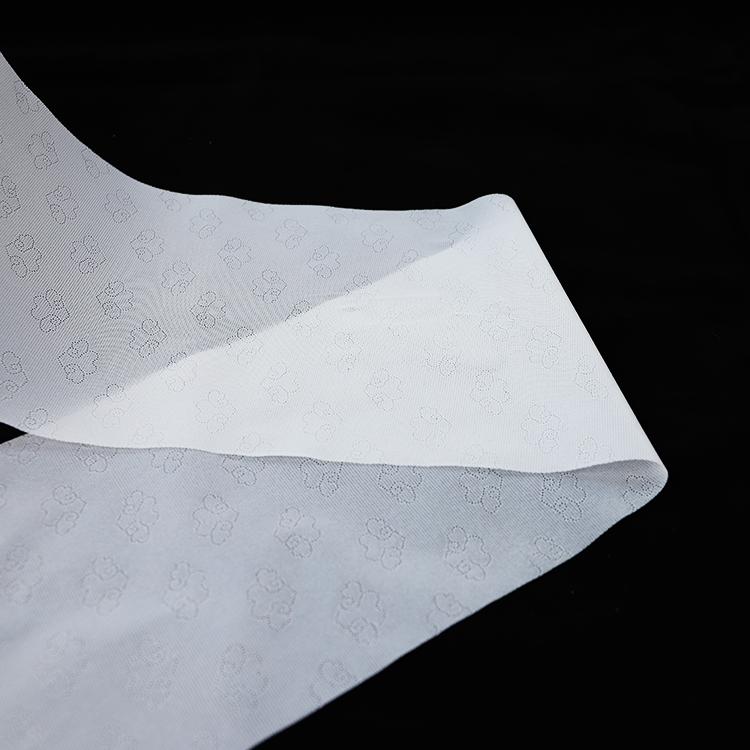

Perforated film topsheet is perforated on the surface of plastic film. This type of hole has a topological structure, that is, the outer layer has a large pore size and the inner layer has a smaller pore size. Therefore, the perforated film topsheet can be used as the surface layer of sanitary products, and the liquid is not easy to reverse osmosis after penetrating into the inner layer.

In the production process of Perforated film topsheet, the raw materials need to be directly put into the screw extruder, through screw extrusion and shearing, the raw materials are heat-plasticized, extruded from the mold, and then through punching, slitting and collecting The perforated film topsheet is made of polyvinyl chloride, polyethylene, polypropylene or polystyrene as the main raw material, combined with inorganic titanium dioxide, antioxidants, lubricants, dispersants and other additives, these After the raw materials are put into the upper hopper together, the raw materials will stick to each other. After entering the screw extruder, the raw materials will condense into a small piece. At present, in order to avoid this situation, the running time of the screw extruder will be lengthened, which will Increase energy consumption and reduce production efficiency.

Based on the technical problem that the existing production method will increase energy consumption and reduce the production efficiency of Perforated film topsheet, Zheng Yuexian, Jiang Shiming and Guo Jinwei proposed a perforated film machine production line: including a screw extruder and a suction machine. The bottom of the feeder is fixedly connected with a hopper, the bottom of the hopper is fixedly connected with a mixer, the mixer is fixedly connected with the screw extruder, and the discharge port of the mixer is connected with the feed port of the screw extruder. The tail end of the screw extruder is connected with a puncher, the tail end of the puncher is connected with a traction mechanism, and the tail end of the traction mechanism is connected with a winder.

The beneficial effect of this production line is:

Transported to the upper hopper, the raw materials in the upper hopper will fall into the mixer due to the influence of gravity. The operation of the mixer can break up the raw materials to prevent the raw materials from agglomerating into small pieces. After the raw materials enter the screw extruder, it can reduce The running time of the screw extruder is reduced, the energy consumption is reduced, and the production efficiency of the perforated film is improved.

Flat roller, synchronous wheel 1, driving motor 1 and synchronous wheel 2, once the driving motor runs, it can drive the synchronous wheel 2 to rotate, and the synchronous wheel 2 can drive the synchronous wheel 1 to rotate through the synchronous belt, which in turn can make the flattening roller rotate. Compared with the existing technology, a drive motor is added to the flattening roller to improve the flatness of the Perforated film topsheet. By setting traction roller 1, traction roller 2, pulley 1, pulley 2, drive motor 2, and pulley 3, the operation of drive motor 2 can drive pulley 3 to rotate, and pulley 3 can drive pulley 1 and pulley 2 to rotate synchronously through the belt, so that the traction Roller 1 and traction roller 2 rotate to pull the Perforated film topsheet, which facilitates the delivery of the Perforated film topsheet after forming. By setting the compression assembly, when the Perforated film topsheet is pulled into between the traction roller 2 and the cooling roller, the cylinder operation can push the installation frame, so that the surface of the cooling roller is in contact with the surface of the perforated film, and the cooling roller and the traction roller The interaction force of the two rollers can cool, press and shape the perforated film to improve the compactness of the perforated film topsheet. At the same time, it can adapt to perforated film topsheets of different thicknesses and improve the use effect.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China