Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-15

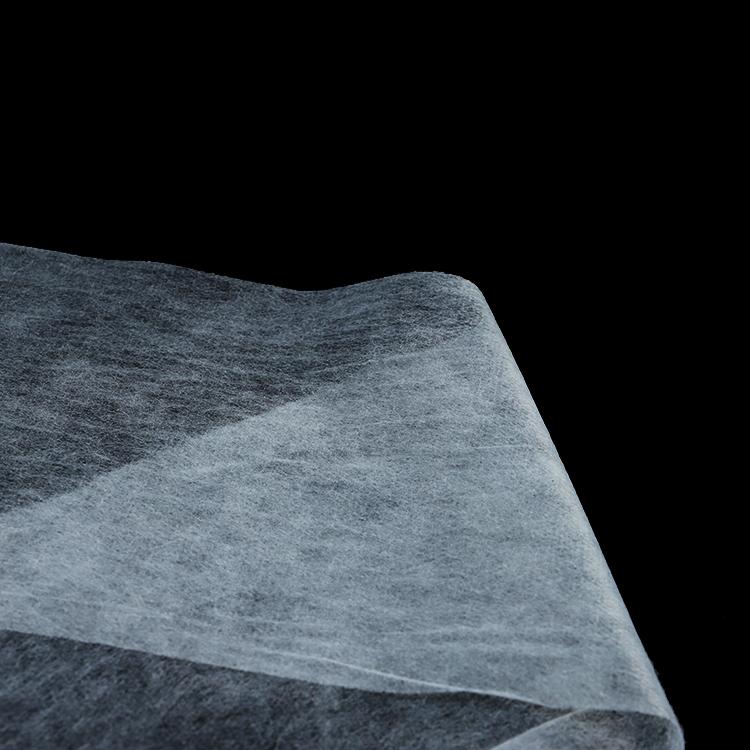

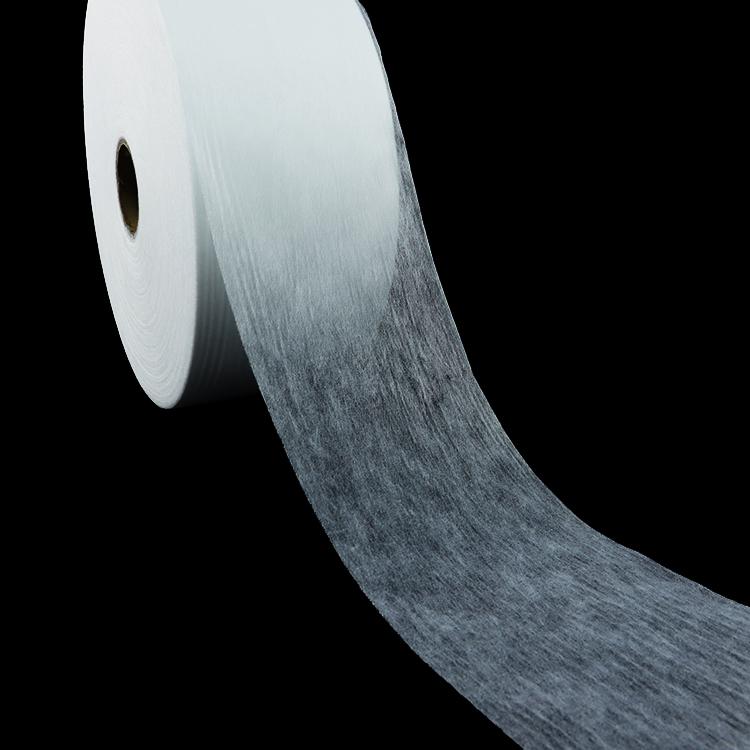

In recent years, my country's spunbonded fabric production capacity has increased significantly. Although the achievements have been remarkable, there are still many gaps compared with foreign countries. At the same time, with the growing market demand, the requirements for spunbond products are getting higher and higher, and the products are developing towards the direction of lightness, homogeneity, diversification and high output, and the production and processing technology of spunbond is proposed higher requirements. This article briefly introduces the development countermeasures of laminated spunbond fabric.

Improve the efficiency of spunbond production by increasing the width, increasing the spinning speed, multi-box technology, positive pressure drafting, increasing the number of spinneret holes, and forming a web by side blowing. Such as the 4.2m production line of Kobe Steel Corporation in Japan, etc., these advanced technologies provide us with reference for technological transformation and innovation, and provide a strong guarantee for improving the production capacity of the production line.

Improve product quality by reducing single fiber fineness, adopting composite spinning technology and differentiation, and improve the shortcomings of traditional spunbond products. For example, spunbonded products made of monofilaments with a fineness below 1dtex increase the number of fibers per unit area of the web, improve product uniformity, and greatly improve the feel of the finished product. Endow spunbond products with antistatic, moisture absorption, dyeing, flame retardant and other properties through differential means to improve the grade of spunbond products. For example: PE/PET skin-core composite products have high strength and excellent waterproof performance; microfiber composite spunbond nonwovens made of different components of PA and PET, due to their stable size and excellent sound absorption effect, can be used In automotive textiles; PP/PE sheath-core type two-component composite spunbonded product, which feels extremely smooth and comfortable, and can be used as an upgraded product for disposable medical and sanitary materials.

In the current situation that my country's equipment manufacturing technology is relatively backward, it should be admitted that there is a big gap with developed countries in equipment production and processing technology. Introduce, digest and absorb, gradually realize localization, and improve product competitiveness.

With the continuous progress of spunbonded nonwovens technology, especially some high-tech applications, its products have great development prospects. However, because the market's understanding and recognition of this product is not deep enough, the professional technical level of the sales staff is limited, especially the formulation of product standards, construction specifications, and inspection methods for the application of nonwovens cannot keep up with the development needs, making Some foreign fields that have been widely used have not yet been developed, and in some fields that have been developed, such as hygiene, geotechnical engineering, building materials, etc., the proportion of spunbonded products is still low. Therefore, the market potential of spunbonded nonwovens is very huge.

Understanding the development countermeasures of laminated spunbond fabric is conducive to the healthy development of the industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China