Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-24

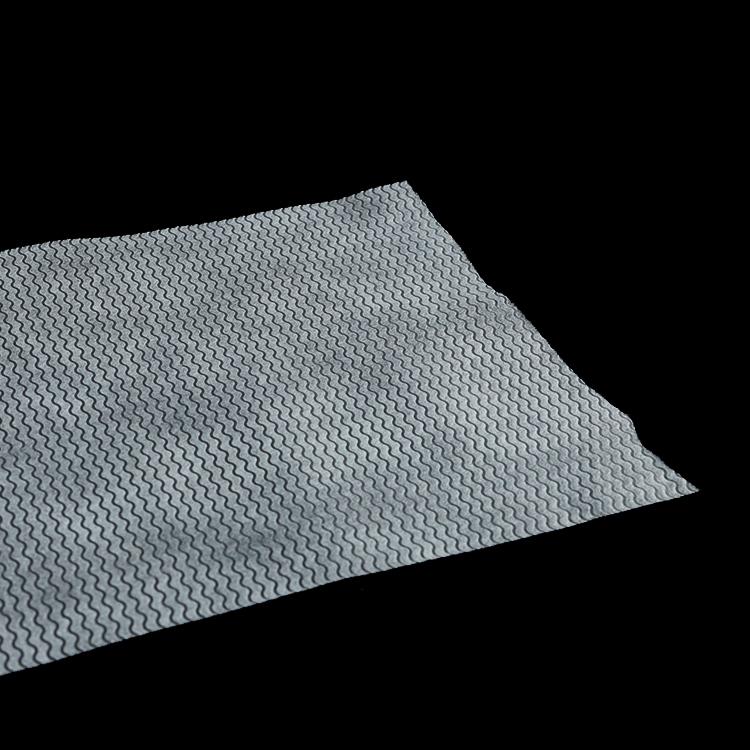

This article introduces the types and development of diaper material, specifically, the types and development of the covering material on the surface of diapers. At present, the coating materials used for the surface layer of diapers mainly include thin short-fiber hot-rolled non-woven fabrics, hot air-through non-woven fabrics and PP spunbonded non-woven fabrics.

A. In the early 1980s, short-fiber hot-rolled nonwovens were produced in China. Because of their good dry and wet strength, good dimensional stability, good hygienic conditions, and good uniformity, they are widely used in disposable fabrics. Medical and health care materials (such as women's sanitary napkins, sanitary pads, adult incontinence pads, diapers, etc.). Users not only require good strength, but also good softness, but the strength and softness of thin hot-rolled nonwovens are a pair of prominent contradictions: good strength, poor softness; good softness, strong and soft Cannot meet usage requirements. In response to this situation, it is often adopted to obtain better softness when the strength meets the minimum requirements for use, or to obtain a certain strength when the softness of the hand meets the minimum requirements for use.

B. In the middle of the 1990s, Xuzhou Feida Company and Fujian Hengan Company introduced air-through nonwoven production lines from Germany and Japan respectively. The hot air process adopts ES composite fibers with C and B double-component skin-core structure. The core layer uses polypropylene with a melting point above 165 degrees, which is a high-melting point component. The skin layer polyethylene is a low-melting point component. The melting point of the skin layer polyethylene is higher than that of the core. The melting point of the layer polypropylene is more than 30 degrees lower. Because the core layer polypropylene has a certain strength, when processing non-woven fabrics, the fiber web is thermally bonded under no pressure, and the low-melting point component polyethylene forms a fusion bond at the cross point of the fiber web, and after cooling The fibers at the intersections of the nonwoven remain in their original state.

Therefore, the hot air-through nonwoven fabric does not have the contradiction between the strength and hand feeling of the hot-rolled fabric, and the thermal stability of the nonwoven fabric is good, and the nonwoven fabric produced by the two-component composite fiber is in a very low thermal shrinkage range. Therefore, the nonwoven fabric is relatively stable whether it is in the hot air process, or in the drying process and post-processing process. C and B bi-component composite fibers are carded, and then penetrated and solidified by hot air to form a nonwoven fabric with a specification of 10 g/m2-50 g/m2, which is suitable for surface materials of paper diapers and women's sanitary napkins.

The continuous improvement and innovation of the production process of sanitary nonwovens has promoted the continuous application of new technology nonwovens characterized by hygiene, safety and comfort in the production of sanitary products. Due to its softness, comfort and moderate strength, hot air-through nonwovens are widely used in sanitary products, gradually replacing hot-rolled nonwovens in its field. Especially after "high softness" became the main development direction of the market in Asia, the hot air process developed rapidly. For example, in 1995, Japanese composite fibers were used in the hot air process, and staple fibers accounted for 59% of the 5.15 tons of nonwovens consumed. , mainly used for cladding materials such as diapers. "High strength and low cost" is the main development direction of European and American markets. European and American people's pragmatism consumption concept and the speed of production equipment for disposable products in Europe and America are constantly improving. High strength and low cost have always been the development direction of European and American diaper material markets.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China