Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-21

Exploring the Versatility of SMMS Material in Diaper Manufacturing

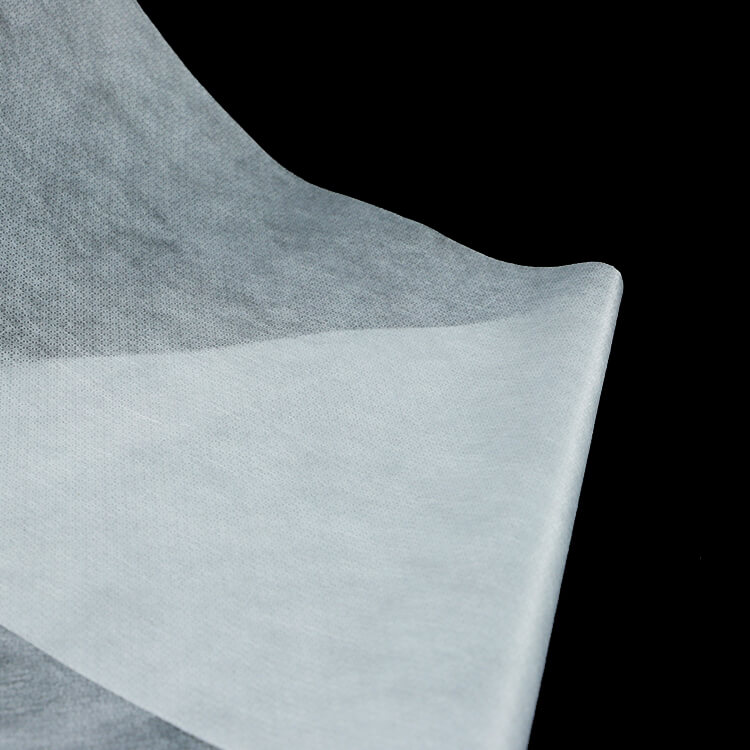

In recent years, there has been a growing demand for diapers that are more absorbent, comfortable, and environmentally friendly. To meet these requirements, manufacturers have turned to SMMS (Spunbond-Meltblown-Meltblown-Spunbond) material, which offers exceptional versatility in diaper production. This article aims to explore the various applications and benefits of SMMS material in the manufacturing process.

One of the key advantages of SMMS material is its enhanced absorbency. The combination of multiple meltblown layers sandwiched between spunbond layers allows for excellent liquid retention. The meltblown layers create a web-like structure with high surface area, enabling rapid absorption and distribution of liquids throughout the diaper. This ensures that the baby's skin stays dry, reducing the chances of irritation and rashes. Furthermore, the superior absorbency of SMMS material enables diapers to handle larger volumes of liquid, making them ideal for overnight use.

Diapers made with SMMS material provide improved comfort and fit for babies. The softness and flexibility of the spunbond layers ensure a gentle touch against the delicate skin. The meltblown layers contribute to the breathability of the diaper, allowing airflow and preventing excessive heat buildup. This ventilation helps to reduce the risk of diaper rash and enhances the overall comfort for the baby. Additionally, the elasticity of SMMS material provides a snug fit, ensuring that the diaper stays securely in place and minimizing the chances of leakage.

Another significant benefit of SMMS material in diaper manufacturing is its positive impact on environmental sustainability. SMMS material can be produced using recycled or biodegradable fibers, reducing the reliance on nonrenewable resources and lessening the carbon footprint of the industry. Moreover, the exceptional durability of SMMS material ensures a longer lifespan for the diaper, reducing waste generation. The combination of enhanced absorbency and fewer diaper changes not only translates into convenience for parents but also contributes to a more sustainable future.

In conclusion, the versatility of SMMS material in diaper manufacturing is undeniable. Its enhanced absorbency, improved comfort and fit, and environmental sustainability make it an ideal choice for modern diaper production. As the industry continues to evolve, SMMS material will undoubtedly play a vital role in meeting the ever-growing demands for high-performance, eco-friendly diapers. With ongoing research and development, we can expect further advancements in SMMS technology, leading to even more innovative and efficient diaper options in the future.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China