Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-24

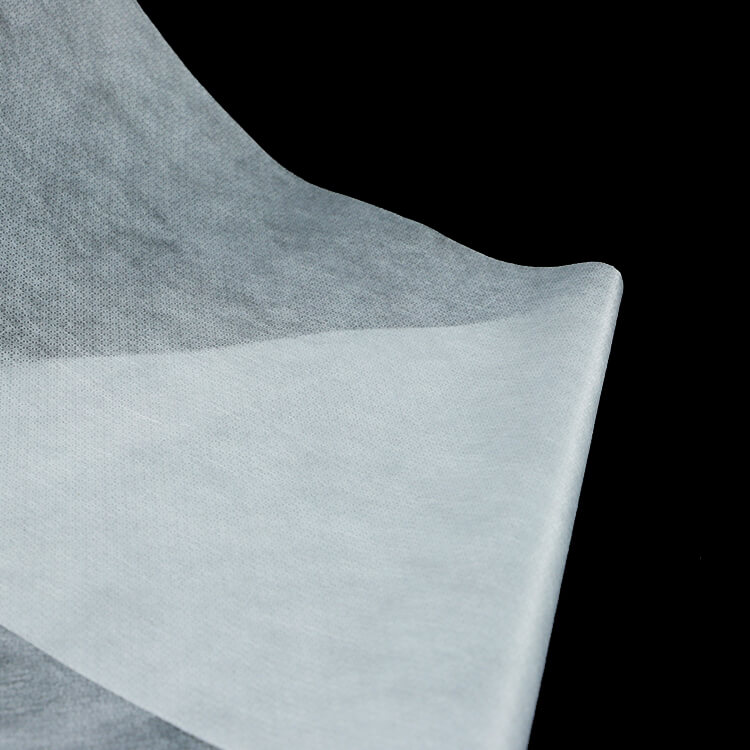

In recent years, diaper manufacturing has undergone a revolutionary change with the introduction of waterproof SMMS (Spunbond-Meltblown-Meltblown-Spunbond) non-woven fabric. This innovative material has transformed the industry, providing superior performance and comfort for both babies and caregivers. In this article, we will explore the benefits and advancements brought about by SMMS non-woven fabric in diaper manufacturing.

One of the key advantages of SMMS non-woven fabric in diaper manufacturing is its enhanced absorption and retention capabilities. The unique structure of the fabric allows for efficient liquid acquisition and distribution, ensuring that moisture is quickly drawn away from the baby's skin and locked within the diaper core.

The meltblown layers in SMMS fabric serve as effective liquid barriers, preventing leakage and keeping the baby's skin dry and comfortable. This advancement has significantly reduced the occurrence of diaper rash and discomfort, making SMMS-based diapers a preferred choice for parents worldwide.

Another remarkable feature of SMMS non-woven fabric is its exceptional softness and breathability. The spunbond layers in the fabric provide a smooth and gentle surface against the baby's skin, minimizing irritation and friction. This ultra-soft texture ensures that babies remain comfortable throughout the day and night.

Furthermore, SMMS fabric allows for optimal air circulation, reducing the risk of excessive heat build-up and perspiration. The breathability of the fabric helps to maintain a constant temperature within the diaper, promoting a healthier and drier environment for the baby. Parents can have peace of mind knowing that their little ones are protected from discomfort and skin irritations.

In addition to its performance benefits, SMMS non-woven fabric brings sustainability advantages to diaper manufacturing. The production process of SMMS fabric requires fewer resources compared to traditional materials, resulting in a lower environmental impact.

Furthermore, SMMS fabric is recyclable and can be used in the production of other non-woven products, reducing waste and contributing to a circular economy. With an increasing emphasis on environmental responsibility, the adoption of SMMS non-woven fabric in diaper manufacturing aligns with the global movement towards sustainability.

In conclusion, the introduction of waterproof SMMS non-woven fabric has revolutionized the diaper manufacturing industry. Its enhanced absorption and retention capabilities, coupled with softness and breathability, have significantly improved the comfort and well-being of both babies and caregivers. Additionally, the eco-friendly nature of SMMS fabric contributes to a more sustainable future. As this revolutionary material continues to evolve, we can expect even more advancements in diaper manufacturing, further enhancing the quality of life for babies around the world.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China