Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-26

Unveiling the Versatility of SMS Material in Diaper Making

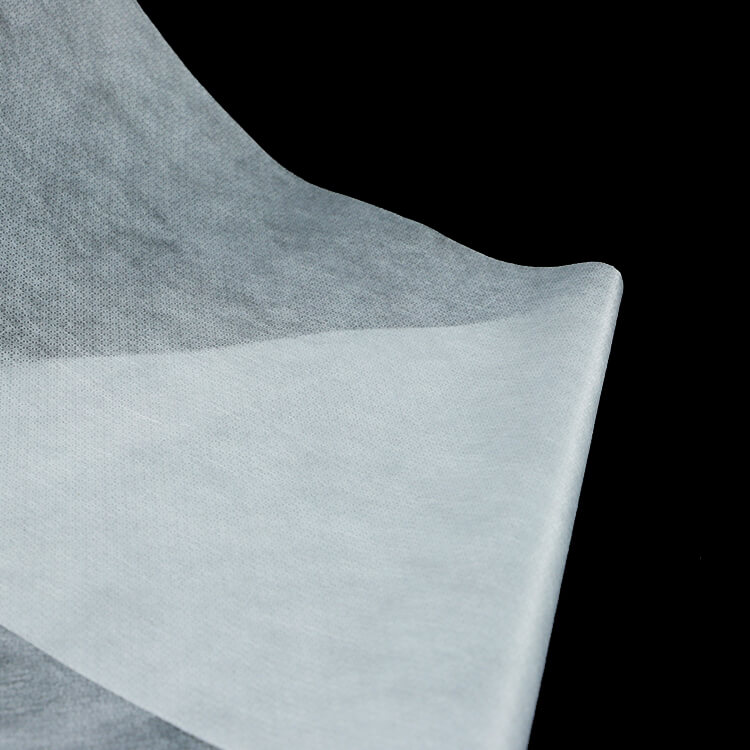

In recent years, the diaper manufacturing industry has witnessed a significant shift towards utilizing SMS (Spunbond-Meltblown-Spunbond) material. This versatile nonwoven fabric has revolutionized the production of diapers, offering numerous benefits such as exceptional liquid absorption, softness, and breathability. In this article, we will explore the various applications and advantages of using SMS material in diaper making.

One of the key reasons why SMS material has gained popularity in diaper manufacturing is its superior liquid absorption capabilities. The combination of spunbond and meltblown layers in SMS fabric creates a highly efficient structure for capturing and locking liquids, preventing leakage and keeping the baby's skin dry. The meltblown layer, with its high surface area and excellent filtration properties, acts as a barrier against liquid penetration. With SMS material, diapers can offer enhanced absorbency, reducing the frequency of diaper changes and providing greater comfort for both infants and parents.

Comfort is crucial when it comes to diapers, and SMS material excels in providing exceptional softness and breathability. The spunbond layers in SMS fabric contribute to the overall softness, making the diaper gentle on the baby's delicate skin. Additionally, the unique structure of SMS material allows for enhanced breathability, promoting better airflow and reducing the risk of irritation and rashes. The breathability of SMS material is especially beneficial during hot weather or when the baby is active. By incorporating SMS fabric into diaper production, manufacturers can prioritize comfort and well-being without compromising on performance.

Besides its outstanding liquid absorption, softness, and breathability, SMS material offers several other advantages in diaper making. First, it provides excellent strength and durability, ensuring that the diaper remains intact even during extended wear. Moreover, SMS fabric is resistant to tearing and punctures, enhancing the overall reliability and longevity of the diaper. Additionally, SMS material is lightweight and has a low cost of production, making it a cost-effective choice for manufacturers. With its versatility and affordability, SMS material has become the preferred option in the diaper manufacturing industry.

The utilization of SMS material has revolutionized the diaper manufacturing industry by offering enhanced liquid absorption, exceptional softness, and breathability. This versatile nonwoven fabric has proven to be a game-changer, providing numerous advantages in terms of comfort, durability, and cost-effectiveness. As technology continues to advance, we can expect further innovations in the field of diaper making, with SMS material at the forefront. The future looks promising as diapers become more comfortable, reliable, and eco-friendly, thanks to the versatile properties of SMS material.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China