Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-07

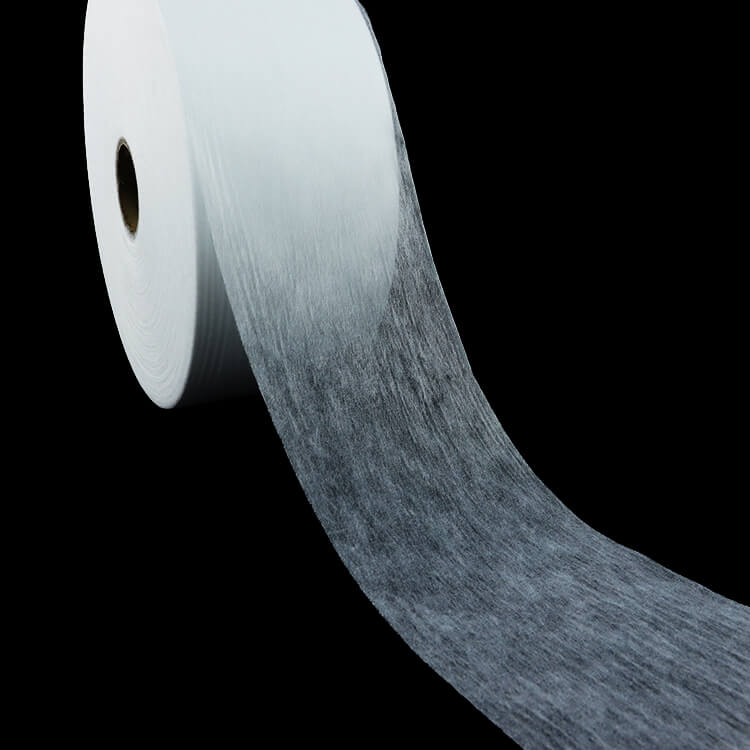

Unleashing the Potential of Non-Woven PP for Superior Diaper Performance

The diaper industry has witnessed significant advancements in recent years, driven by the quest for more comfortable, absorbent, and durable products. Among the various materials used in diaper manufacturing, non-woven polypropylene (PP) has gained immense popularity due to its unique properties. This article aims to explore the untapped potential of non-woven PP and its ability to enhance diaper performance.

Non-woven PP offers superior absorbency compared to traditional materials like cotton or fluff pulp. Its high surface area and capillary action allow for quick absorption of liquid, ensuring that the baby's skin remains dry and comfortable. Additionally, non-woven PP has excellent wetness distribution capabilities, evenly spreading the absorbed liquid throughout the diaper, reducing the risk of leakage and discomfort.

Furthermore, non-woven PP can be engineered to have different thicknesses and densities, allowing for customized absorbency levels. Manufacturers can strategically place thicker layers in areas that require higher absorbency, such as the center of the diaper, while using thinner layers in other areas. This targeted approach maximizes the overall absorbent capacity of the diaper and ensures efficient usage of resources.

One of the key challenges in diaper design is balancing absorbency with breathability. While it is essential for the diaper to absorb moisture, it is equally important to allow air circulation to prevent discomfort and rashes. Non-woven PP excels in this aspect, as it has inherent breathable properties.

The porous structure of non-woven PP enables the flow of air, facilitating the evaporation of moisture from the diaper. This helps in maintaining a dry and cool environment, reducing the likelihood of skin irritation. Moreover, the lightweight nature of non-woven PP contributes to the overall comfort of the diaper, ensuring that the baby can move freely without any bulkiness or restriction.

Diapers made with non-woven PP exhibit superior durability compared to those made with traditional materials. The strong and tear-resistant nature of non-woven PP ensures that the diaper remains intact even during rigorous activities, minimizing the risk of leaks and discomfort for the baby.

Additionally, non-woven PP offers cost efficiency in diaper manufacturing. Its high production rate and ease of processing make it a cost-effective choice for manufacturers. Moreover, the lightweight nature of non-woven PP reduces transportation costs and storage space requirements, further enhancing its economic viability.

The utilization of non-woven PP in diaper manufacturing has revolutionized the industry by providing enhanced absorbency, wetness distribution, breathability, comfort, durability, and cost efficiency. As manufacturers continue to push the boundaries of innovation, it is expected that non-woven PP will play an increasingly significant role in shaping the future of diaper performance. By embracing this material's potential, we can ensure that babies experience superior comfort and protection, contributing to their overall well-being.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China