Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-21

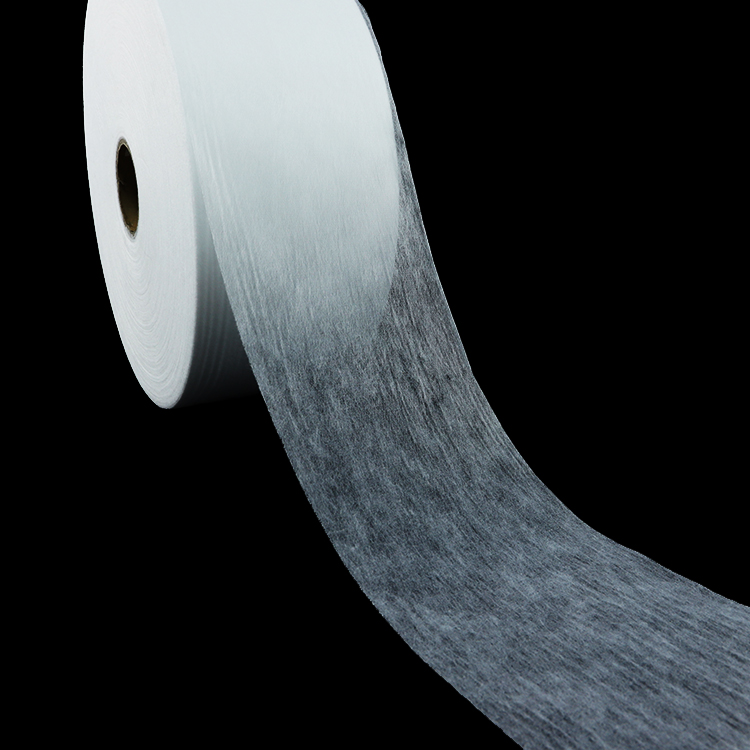

Understanding the Benefits of Thermal Bond Nonwoven Fabric in Diaper Making

Diapers are an essential item in the daily lives of infants and toddlers, providing them with the comfort and protection they need. With the advancement of technology, diaper manufacturers are constantly seeking innovative materials to enhance the performance of diapers. One such material is thermal bond nonwoven fabric, which offers a range of benefits that improve the overall quality and functionality of diapers. This article will explore the various advantages of thermal bond nonwoven fabric in diaper making.

One of the key benefits of using thermal bond nonwoven fabric in diaper making is its enhanced absorbency. The unique composition and structure of this fabric allow for greater liquid retention, keeping the baby's skin dry and preventing discomfort. The thermal bonding process creates a three-dimensional network of fibers, which promotes rapid absorption and distribution of moisture throughout the diaper. As a result, leaks and spills are minimized, ensuring that the baby stays dry and comfortable for longer periods.

In addition to its absorbent properties, thermal bond nonwoven fabric also offers improved breathability. Diapers made with this fabric allow for better airflow, reducing the risk of diaper rash and skin irritation. The thermal bonding process ensures that the fabric retains its porous structure, allowing moisture vapor to escape while preventing the entry of external liquids. This breathability feature helps to maintain a healthy and hygienic environment for the baby's delicate skin, even during extended wear.

Thermal bond nonwoven fabric provides an enhanced level of softness and comfort for babies. The fibers used in this fabric are meticulously processed to create a smooth and gentle texture that is gentle on the skin. The thermal bonding process further enhances the fabric's softness, creating a cushion-like feel against the baby's delicate skin. This softness and comfort factor is crucial in preventing irritation and ensuring that the baby remains content and happy throughout the day and night.

In conclusion, thermal bond nonwoven fabric offers several significant benefits in diaper making. Its enhanced absorbency, improved breathability, and enhanced softness and comfort make it an ideal material for producing high-quality diapers. As diaper manufacturers continue to prioritize the well-being and comfort of infants and toddlers, the use of thermal bond nonwoven fabric is expected to become increasingly prevalent in the industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China