Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-16

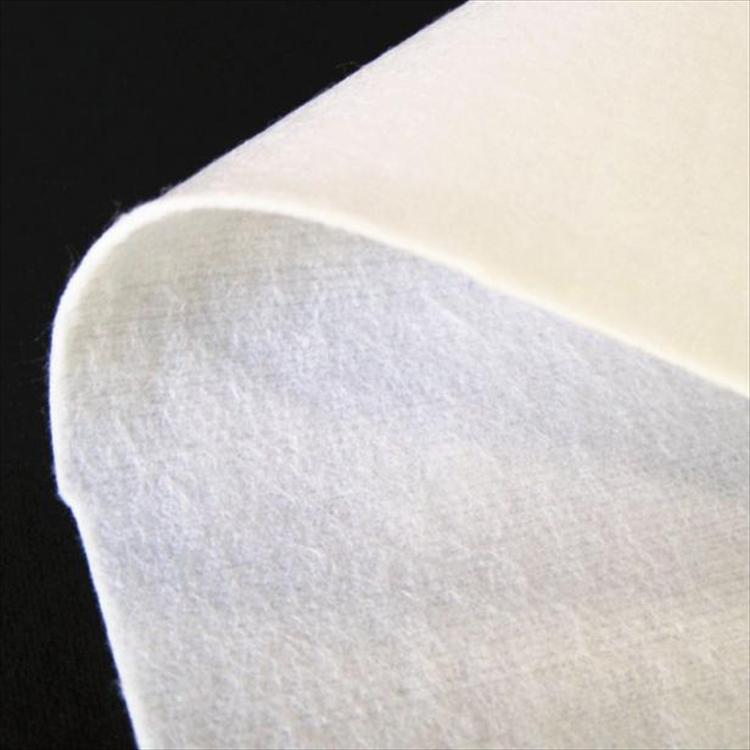

Spunlace technology has good development potential and prospects in the field of nonwoven production, and is a sunrise industry. Compounding is a common way of producing high-performance and highly functional products in the nonwovens industry. In this paper, a composite material is prepared by bonding wood pulp paper and viscose fiber spunlace non woven fabric with water-based acrylic resin, and the physical properties of this spunlace non woven fabric are analyzed.

With the increase of the selected wood pulp paper weight, the fracture strength of the composite material showed obvious changes, and both the longitudinal and transverse fracture strengths showed an increasing trend. In the material composite scheme, the elongation at break value of each composite material is between the two materials. Through the fracture strength and elongation index of the composite material, it indirectly reflects that the water-based acrylic resin solution has a better bonding effect on wood pulp paper and viscose fiber spunlace nonwoven fabric, which improves the overall fracture strength of the composite material and improves the composite material. Elongation at break index.

There are many factors affecting the thickness of composite materials, which are affected by factors such as raw materials, coating amount of water-based acrylic resin, rolling pressure and moisture of composite materials. In this experiment, the overall thickness of the composite material is between the thickness of the wood pulp paper and the thickness of the viscose fiber spunlace nonwoven fabric. With the increase of the weight of the wood pulp paper, the thickness of the composite material shows a slight increase. , but the overall impact is small.

The liquid absorption of wood pulp paper is closely related to the porosity of the paper sheet. The absorption performance of wood pulp paper is the penetration between fibers and within fibers. The wood pulp paper can be adjusted through the selection of fiber raw materials, beating process, dewatering process on the Internet, drying conditions, etc. of liquid absorption. The liquid absorption of spunlace nonwovens is related to the fiber composition and product structure. The fiber raw materials need to contain hydrophilic groups, and there are pores inside the material. In addition, the factors that affect the water absorption include fabric density, surface area, fiber fineness, fiber arrangement, etc.

In this experiment, different quantitative wood pulp paper and viscose fiber spunlace cloth were adhesively compounded. The liquid absorption height of the composite material was 85-92 mm, which was between the liquid absorption height of wood pulp paper and viscose fiber spunlace cloth. With the increase of the basis weight of wood pulp paper, the liquid absorption height of the composite material showed an upward trend.

The properties of wood pulp paper and viscose fiber spunlace nonwoven adhesive composite materials will open up broad application prospects for it. Understanding the physical indicators of spunlace non woven fabric composites will help people to better apply this new material.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China