Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-07

We all know that there are different types of raw material for diaper manufacturing. The absorbency factor in raw material for diaper manufacturing varies from one raw material for diaper manufacturing to another. Some people are not very familiar with the properties of the absorbency factor and do not know whether it is better to have more or less absorbency factor in nappies. Today we will discuss the issue and see whether it is better to have more or less absorbency in raw material for diaper manufacturing.

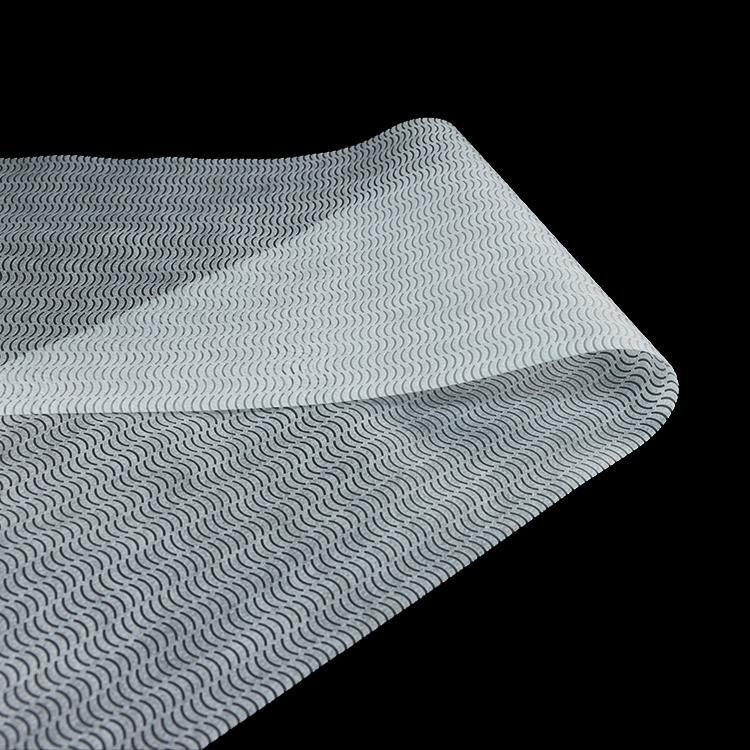

A. How much absorbency is better in a diaper. Among the absorption factors of diapers, there are two main types of absorbent material: the first is a polymer absorbent material and the second is an absorbent resin. One is the speed of water absorption, the second is the amount of water absorbed, the third is whether the water will seep back into the diaper after absorption, and there is another key point that is easily overlooked, and that is the infusion, whether it will spread out evenly. If the above points are met, then it is a diaper with good absorbency, and to make a good diaper, a good diaper has softness and comfort, fast absorption, large absorption, dryness without re-infiltration, good breathability, anti-side-leakage, no breakage, no lump, if all these are met, it should be a good nappy.

B. Polymeric absorbent resin is a typical functional polymer. It can absorb hundreds, even thousands, of times its own weight of water and has a high water retention capacity, so it is also known as a super absorbent or high water retention agent. In the actual production of SAP and lint fiber is mixed evenly is very important, which is directly related to the size of the product's absorption performance and the uniformity of the absorption, but also to avoid the production of gel adhesion and hard points sticking through the paper web surface, to prevent the layer between the sliding has an important role to play.

C. SAP in the maximum amount of dust-free paper can be up to 55%, the amount of SAP in dust-free paper generally depends on the use of the product. If used as a sanitary napkin in the absorbent core layer of small look pads, etc., the amount of SAP is 20-25%, if used as a baby nappy, adult incontinence products, agricultural and forestry water retention, the amount of SAP in 30-35%.

A.The water absorption factor in sanitary napkin materials is: the highly efficient gelling layer, which is made of polymeric water-absorbent resin. Sanitary napkins with a highly efficient gelatinised layer can condense the infiltrated liquid into a gel-like consistency, which does not bleed back under pressure and has no sticky feeling on the surface. The material usually used is a polymeric absorbent resin.

B.Polymeric absorbent resin is a typical functional polymer. It can absorb water hundreds or even thousands of times its own weight and has a strong water retention capacity, so it is also known as a super absorbent or a high water retention agent. Highly absorbent resins are low cross-linked or partially crystalline polymers with many hydrophilic groups. They are mainly used in the hygiene sector for sanitary napkins, raw material for diaper manufacturing

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China