Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-15

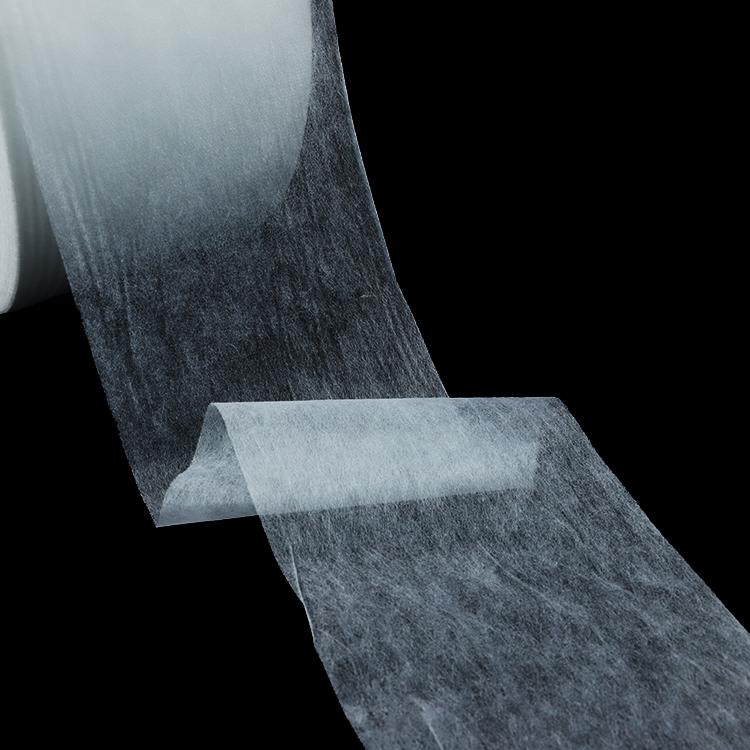

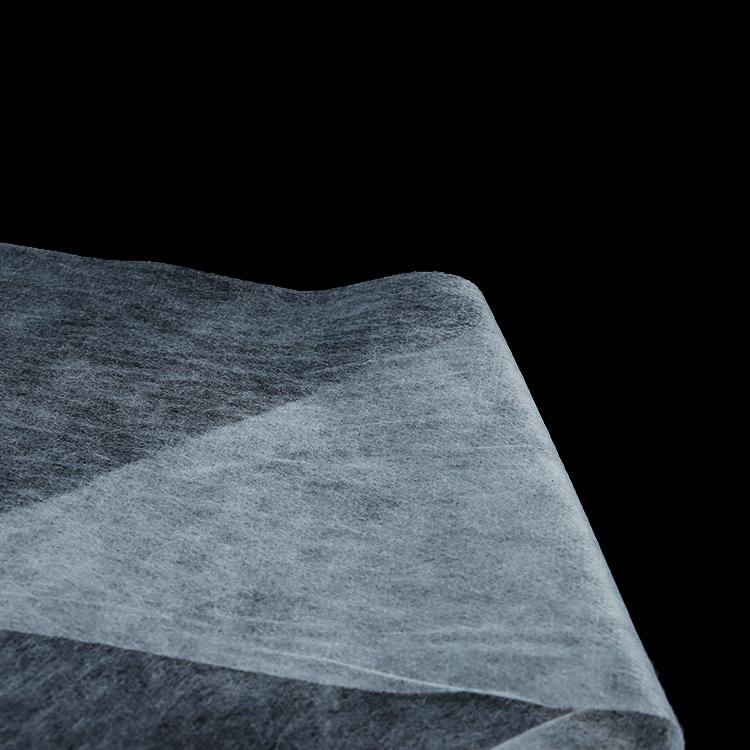

Baby diapers currently sold in the Chinese market generally consist of three parts: surface covering layer, absorbent core layer and base fabric. The surface coating material of diapers is basically Hydrophilic spunbond non woven fabric topsheet of 13~15g/square meter. The coating is close to the baby's body, and it is required to promote the rapid penetration of urine and effectively prevent back seepage, keep dry, and cover. Good, soft and comfortable without irritating the skin. This paper discusses Hydrophilic spunbond non woven fabric topsheet, in order to provide reference for relevant researchers.

Hydrophilic spunbond non woven fabric topsheet is mainly a non-woven fabric formed from polypropylene slices extruded by a screw extruder, melt spun into a web, and the fiber web is bonded and consolidated by hot rolling. Because polypropylene has a non-polar structure, high crystallinity and no hydrophilic group in the molecule, and the cross-section of the fiber is round, the structure is dense and lacks micropores and gaps, so the hygroscopicity of polypropylene spunbonded nonwovens is poor. When polypropylene spunbonded nonwovens are used as disposable sanitary materials, especially when the surface material of baby diapers is used, hydrophilic finishing must be carried out to improve their hydrophilicity.

There are many ways to improve the hydrophilicity of Hydrophilic spunbond non woven fabric topsheet and improve the wettability of the fiber surface, which can be roughly divided into two categories: one is to modify the fiber during the spinning stage to obtain the hydrophilicity of the fiber (Adding hydrophilic substances to polypropylene masterbatches/adding hydrophilic masterbatches during spinning), the second type is to use post-finishing methods to modify the surface of nonwoven fabrics to hydrophilicity (a widely used method, Mainly divided into three methods: padding, spraying, KissRoll oil roller coating).

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China