Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-25

Unleashing the Power of SMMS Material in Diaper Production

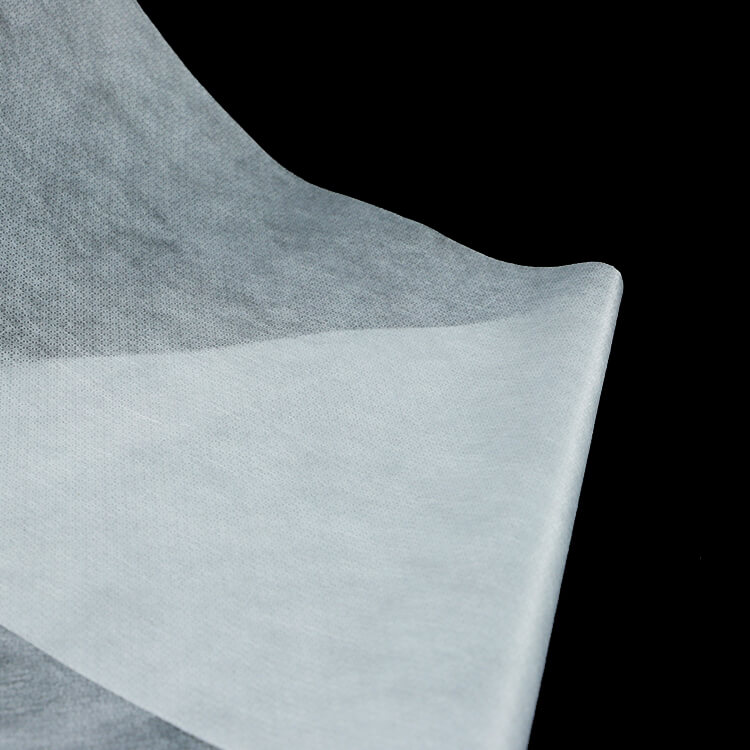

In recent years, the diaper industry has seen significant advancements in materials and technology. One such breakthrough is the utilization of SMMS (Spunbond-Meltblown-Meltblown-Spunbond) material in diaper production. SMMS offers superior performance in terms of absorbency, softness, and efficiency. This article aims to explore the benefits of SMMS material in diaper manufacturing and its potential to revolutionize the industry.

One of the primary advantages of SMMS material in diaper production is its enhanced absorbency. The unique combination of spunbond and meltblown layers allows for efficient liquid absorption, preventing leakage and keeping the baby's skin dry. The meltblown layers provide an intricate network of fine fibers that trap moisture while maintaining breathability. Compared to traditional materials, diapers made with SMMS exhibit a significantly higher absorbency rate, thereby reducing the frequency of diaper changes and ensuring maximum comfort for babies.

Another significant benefit of using SMMS material in diaper production is the improved softness and comfort it offers. The spunbond layers in SMMS provide a smooth and gentle surface that is delicate on the baby's skin. Additionally, the meltblown layers contribute to the material's softness by creating a cushioning effect, minimizing friction and irritation. This optimal combination of softness and comfort is crucial for maintaining healthy skin and preventing diaper rashes. Diapers made with SMMS material provide a luxurious feel for babies, ensuring a happier and more comfortable experience.

SMMS material also offers notable advantages in terms of efficiency and cost-effectiveness in diaper production. The manufacturing process of SMMS involves a high degree of automation, allowing for precise control of layer thickness and uniformity. This results in consistent product quality and reduced production waste. Moreover, SMMS material is lightweight, which translates to lower transportation costs and increased logistical efficiency. The durability of SMMS further adds to its cost-effectiveness, as diapers made with this material are less prone to tearing or leaking, reducing the need for replacements.

The utilization of SMMS material in diaper production has proven to be a game-changer for the industry. With improved absorbency, enhanced softness, and remarkable efficiency, SMMS offers numerous advantages over traditional materials. By incorporating SMMS into their manufacturing processes, diaper companies can provide parents with superior products that prioritize the comfort and well-being of their little ones. As the demand for high-quality diapers continues to grow, it is clear that SMMS material will play a vital role in shaping the future of diaper production.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China