Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-30

Water resistant spunbond is a crucial component in the production of diapers, providing the necessary barrier against leaks and keeping babies dry and comfortable. Understanding the essential knowledge about water resistant spunbond is vital for diaper manufacturers to ensure the quality and performance of their products. This article aims to provide a comprehensive overview of the key aspects related to water resistant spunbond in diaper production.

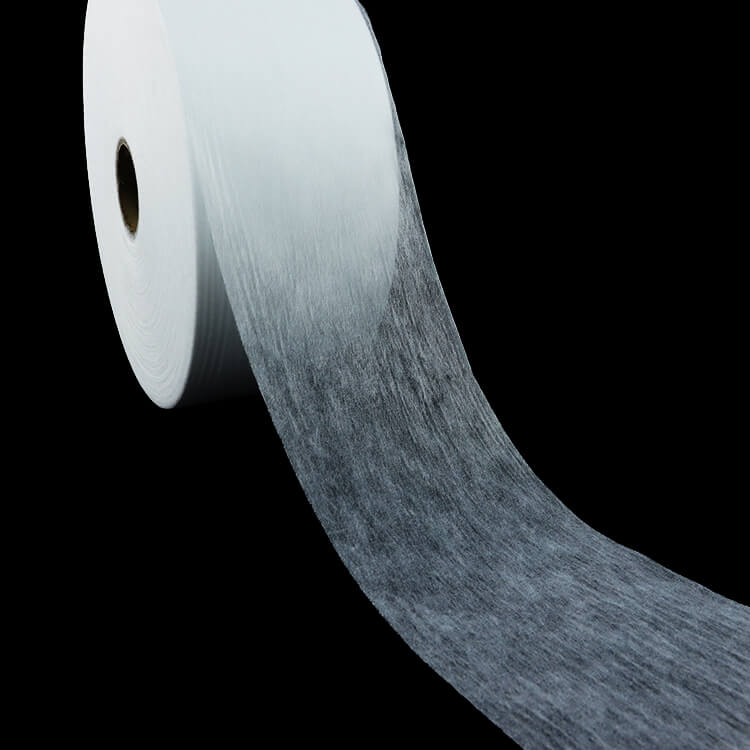

Water resistant spunbond is a type of nonwoven fabric that is specially designed to repel liquids, such as urine and other fluids. It is commonly used as a top sheet or back sheet in diapers to prevent leakage and keep the baby's skin dry. Unlike regular spunbond, water resistant spunbond is treated with various technologies and finishes that enhance its ability to resist liquid penetration while maintaining breathability.

Water resistant spunbond possesses several important properties and features that make it an ideal choice for diaper production:

- Liquid repellency: The primary characteristic of water resistant spunbond is its ability to repel liquids. This ensures that the diaper remains dry and prevents leakage.

- Breathability: Despite its liquid repellent properties, water resistant spunbond allows air to pass through, ensuring proper ventilation and reducing the risk of skin irritation.

- Softness: Comfort is crucial in diapers, and water resistant spunbond provides a soft and gentle touch on the baby's delicate skin.

- Durability: Diapers endure frequent movements and stretches, so water resistant spunbond must be strong and withstand these stresses without tearing or breaking.

The manufacturing process of water resistant spunbond involves several stages, including extrusion, spinning, web formation, bonding, and finishing. Quality control is essential throughout these processes to ensure the final product meets the required standards. Inspection and monitoring are conducted for parameters such as basis weight, tensile strength, elongation, liquid repellency, and uniformity.

Different quality control tests are performed, such as hydrostatic head testing, which measures the fabric's ability to resist a certain level of liquid pressure without penetration. Additionally, tests for breathability, softness, and abrasion resistance are conducted to ensure the overall performance and durability of water resistant spunbond in diaper production.

In conclusion, water resistant spunbond plays a vital role in ensuring the quality and functionality of diapers. Understanding its properties, manufacturing process, and quality control measures is essential for diaper manufacturers. By utilizing water resistant spunbond effectively, they can produce high-quality diapers that provide superior protection and comfort for babies.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China