Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-07

Unveiling the Applications of Spunbond Material in Diaper Manufacturing

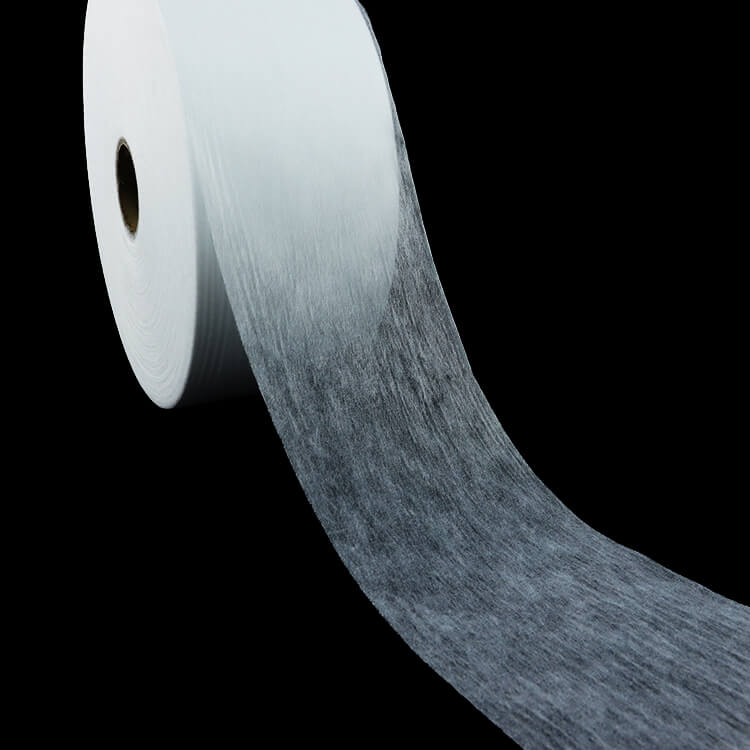

In recent years, the diaper manufacturing industry has witnessed significant advancements in materials and technology. One such material that has gained prominence is spunbond nonwoven fabric. Spunbond is a unique material with various beneficial properties that make it ideal for diaper production. From its excellent strength and durability to its ability to provide superior comfort and functionality, spunbond has revolutionized the diaper manufacturing process. This article explores the applications of spunbond material in diaper manufacturing and highlights the advantages it offers to both manufacturers and consumers.

Spunbond material plays a crucial role in enhancing the absorbency of diapers. By incorporating spunbond layers, manufacturers improve the overall performance of the diaper by increasing its absorption capacity. The spunbond material has a high surface area, allowing it to effectively distribute liquid and prevent leakage. Its inherent hydrophilic nature ensures quick absorption and locks away moisture, keeping the baby's skin dry and comfortable. Additionally, spunbond fabric resists deformation when wet, maintaining its integrity and preventing sagging, which further contributes to leak prevention.

Another significant advantage of using spunbond material in diaper manufacturing is its softness and breathability. For a product that comes into direct contact with a baby's delicate skin, comfort is of utmost importance. Spunbond fabric is incredibly soft and gentle, providing a smooth surface against the baby's skin and minimizing the risk of irritation or rashes. Furthermore, the structure of spunbond material allows air circulation, promoting breathability and reducing the chances of discomfort caused by heat and humidity. This breathability is essential in maintaining the overall health and well-being of the baby's skin.

Spunbond material offers a cost-effective solution for diaper manufacturers. Its production process is efficient and results in a high yield, making it a viable choice for large-scale production. Additionally, the durability of spunbond fabric ensures that diapers withstand rigorous usage, reducing the need for frequent diaper changes and lowering overall costs for consumers. From an environmental standpoint, spunbond material is also a sustainable option. It is manufactured using non-toxic materials and is recyclable, contributing to waste reduction and promoting eco-friendly practices within the diaper manufacturing industry.

In conclusion, the applications of spunbond material in diaper manufacturing are extensive and transformative. Its enhanced absorbency and leakage prevention properties, combined with its softness and breathability, make it an ideal material for producing high-quality diapers. Moreover, the cost-effectiveness and sustainability of spunbond material further consolidate its position as a preferred choice for manufacturers and consumers alike. As the diaper industry continues to innovate, spunbond material will undoubtedly play a crucial role in shaping the future of diaper manufacturing.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China