Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-07

Unveiling the Versatile Applications of Laminated Spunbond Fabric in Diaper Production

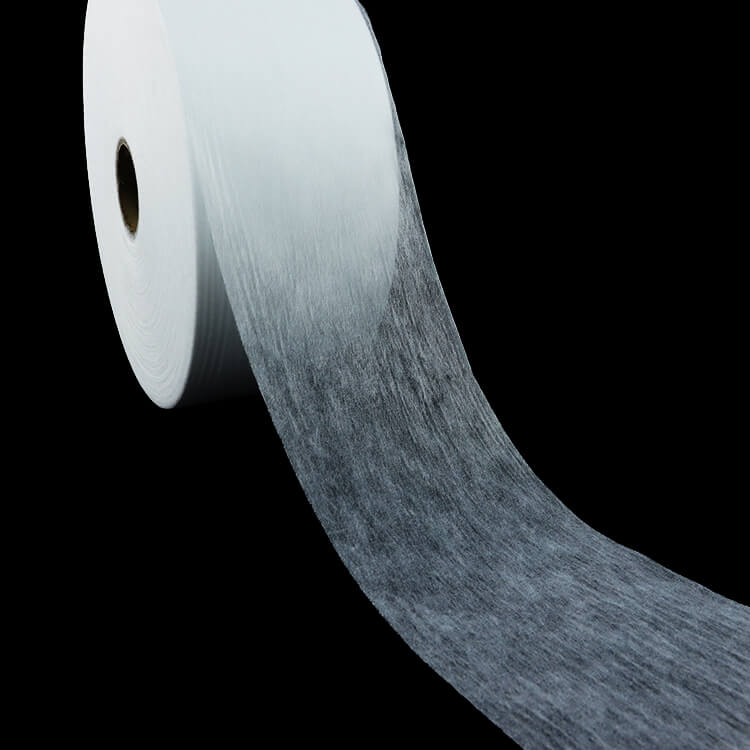

Diapers play a crucial role in maintaining hygiene and comfort for infants and adults with special needs. The evolution of diaper production has witnessed remarkable advancements in materials and technologies. Laminated spunbond fabric, an innovative material, has gained significant traction in the manufacturing of diapers. This article aims to explore the versatile applications of laminated spunbond fabric in diaper production, highlighting its benefits and impact on the industry.

One of the key advantages of laminated spunbond fabric in diaper production lies in its enhanced absorbency properties. The non-woven structure of spunbond fabric allows for efficient liquid absorption, preventing the formation of pools that can cause discomfort and promote skin irritation. By incorporating additional lamination layers, diaper manufacturers can further enhance absorbency and prevent leakage, ensuring dryness and comfort for extended periods. The use of laminated spunbond fabric eliminates the need for additional absorbent gels or chemicals, making diapers safer and more eco-friendly.

Laminated spunbond fabric exhibits excellent breathability, allowing air circulation through the diaper. This feature is particularly important to maintain healthy skin and prevent rashes or irritations. The porous nature of spunbond fabric enables the escape of heat and moisture, keeping the skin dry and reducing the risk of diaper rash. Additionally, the soft and smooth texture of laminated spunbond fabric contributes to the gentle touch on the skin, minimizing friction and maximizing comfort. Babies and individuals with sensitive skin greatly benefit from these skin-friendly attributes of laminated spunbond fabric diapers.

Laminated spunbond fabric offers manufacturers a high degree of flexibility and customization options in diaper production. The material can be easily molded into different shapes and sizes, accommodating various body types and ensuring a snug fit. By laminating multiple layers of spunbond fabric, diaper manufacturers can create zones of different absorbency levels, targeting specific areas prone to more frequent moisture exposure. Additionally, the versatility of laminated spunbond fabric allows for the incorporation of features like wetness indicators and stretchability, further enhancing the user experience and convenience.

Laminated spunbond fabric has revolutionized the diaper production industry, offering a wide range of benefits and applications. From its enhanced absorbency and leakage prevention properties to its breathability and skin-friendliness, laminated spunbond fabric provides unparalleled comfort and hygiene for diaper users. Furthermore, its flexibility and customization options allow manufacturers to cater to diverse consumer needs. As technology continues to advance, the utilization of laminated spunbond fabric in diaper production is expected to expand, ushering in a new era of comfort, sustainability, and innovation in the diaper market.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China